Ridgid 100-B Owners Manual - Page 5

Specific Safety Information, Description, Specifications and, Standard Equipment - propress

|

View all Ridgid 100-B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

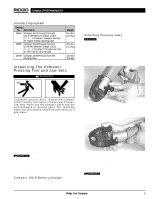

Compact 100-B Pressing Tool • Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for one tool may become hazardous when used on another tool. • Keep handles dry and clean; free from oil and grease. Allows for better control of the tool. Service • Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified repair personnel could result in injury. • When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance Section of this manual. Use of unauthorized parts or failure to follow Maintenance Instructions may create a risk of electrical shock or injury. Specific Safety Information WARNING Read this Operator's Manual carefully before using the RIDGID Compact 100-B Pressing Tool. Failure to understand and follow the contents of this manual may result in extensive property damage, severe personal injury, or death. Call the Ridge Tool Company, Technical Service Department at (800) 519-3456 if you have any questions. Pressing Tool Safety • Only use the Compact 100-B Pressing Tool with RIDGID Compact ProPress® jaws or RIDGID Compact PureFlow™ Viega jaws and fittings. Other uses or modifying the Compact 100-B Pressing Tool for other applications may damage the pressing tool, damage the jaws and/or cause personal injury. • Keep your fingers and hands away from jaws during pressing cycle. Your fingers or hands can be crushed, fractured or amputated if they become caught between the jaws or between these components and any other object. • Never attempt to repair a damaged jaw set. A jaw that has been welded, ground, drilled or modified in any manner can shatter during pressing resulting in serious injury. Discard the entire damaged jaw set. Replace with a new jaw set. Never replace individual components except for damaged jaw return springs. Please call Ridge Tool Company, Technical Services for availability. • Never use tool with a switch or motor housing that is damaged. Using a tool with a cracked motor housing or broken switch can result in electric shock and severe injury. Battery Charger Safety • Charge only Makita® Ni-MH and Ni-Cd rechargeable batteries in the Makita® battery charger. Other types of batteries may burst causing personal injury and damage. • Do not probe battery charger with conductive objects. Shorting of battery terminals may cause sparks, burns or electrical shock. • Do not insert battery with cracked case into charger. Do not operate charger if it has been dropped or damaged in any way. Damaged charger increases the risk of electrical shock. • Do not burn batteries for any reason. Batteries explode in fire. • Charge battery cartridge in temperatures above 50°F (10°C) and below +104°F (40°C). Store tool and battery pack in locations where temperatures will not exceed +120°F (49°C). Proper care will prevent serious damage to batteries. Improper care of batteries may result in battery leakage, electrical shock or burns. • Do not attempt to use a step-up transformer, an engine generator or DC power receptacle. May cause damage to charger resulting in electrical shock, fire or burns. • Do not allow anything to cover the charger while in use. May result in fire. • Unplug the charger when not in use. Reduces risk of injury to children and untrained persons. • Always cover the battery terminals with the battery cover when the battery cartridge is not used. Reduces risk of electrical shock. • Do not charge battery pack in damp or wet environment. Do not expose to rain or snow. Increases the risk of electrical shock. Description, Specifications and Standard Equipment Description The Compact 100-B Pressing Tool, when used with appropriate jaw sets, is designed to mechanically press fittings onto tubing to create a water-tight and permanent seal. When the switch on the Compact 100-B is depressed, an internal electric motor powers a hydraulic pump which forces fluid into the cylinder of the tool, forcing the ram for- Ridge Tool Company 3