Ridgid 100-B Owners Manual - Page 9

Operating Instructions - tool

|

View all Ridgid 100-B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

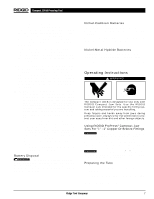

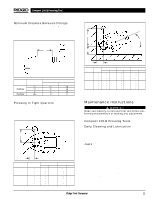

Compact 100-B Pressing Tool 2. If you charge a battery cartridge from a just-operated tool or a battery cartridge which has been left in a location exposed to direct sunlight or heat for a long time, the charging light may flash in red color. If this occurs, wait for a while. Charging will begin after the battery cartridge cools. The battery cartridge will cool faster if you remove the battery cartridge from the battery charger. 3. If the charging light flashes alternately in green and red color, a problem exists and charging is not possible. The terminals on the charger or battery cartridge are clogged with dust or the battery cartridge is worn out or damaged. 4. Batteries should be removed from the Compact 100B Pressing Tool when the tool is being stored, especially when stored for lengthy periods of time. The tool electronics represent a very slight drain on the battery when the battery is installed. Leaving a battery plugged in the tool for long periods of time may result in overdischarging a battery and can cause permanent battery damage. NOTE! Battery performance is severely reduced when batteries are stored below 32°F (0°C). For optimal tool performance and battery life per charge in cold climates, take care to keep batteries as warm as possible. When battery temperatures are kept above 32°F (0°C), the number of press cycles is dramatically improved, especially on larger diameter fittings. Other suggestions for improving battery performance: • Use the tool to make pressed connections as soon as possible after transferring the battery from a warm storage environment to a freezing or subfreezing operating environment. Planning ahead in this manner will significantly improve the number of connections achieved before battery requires recharging. • Be sure to fully discharge the battery before recharging. • Follow proper recharging procedures as spelled out on pages 6-7 of this manual. Battery Disposal WARNING Do not attempt to disassemble the battery or remove any component projecting from the battery terminals. Fire or injury may result. Prior to disposal, protect exposed terminals with heavy insulating tape to prevent shorting. Nickel-Cadmium Batteries If equipped with nickel-cadmium battery, the battery must be collected, recycled or disposed of in an environmentally sound manner. Please call 1-800-8-BATTERY for information on Ni-Cd battery recycling and disposal bans/restrictions in your area. Nickel-Metal Hydride Batteries If equipped with a nickel-metal hydride battery, the battery can be disposed of in a municipal solid waste stream. Contact your local government for disposal or recycling practices in your area. Operating Instructions WARNING The Compact 100-B is designed for use only with RIDGID Compact Jaw Sets. Use the RIDGID Compact Jaw intended for the specific fitting system and tubing material you are installing. Keep fingers and hands away from jaws during pressing cycle. Always wear eye protection to protect your eyes from dirt and other foreign objects. Using RIDGID ProPress® Compact Jaw Sets For 1/2″ - 1″ Copper Or Bronze Fittings CAUTION To obtain a proper seal, the tube end should be squarely cut and must be inserted in the fitting the correct depth (refer to Insertion Depth Table). Jaw set must be square to the tube and properly aligned with the contour of the fitting. Failure to do so may result in an improper seal that can lead to extensive property damage. CAUTION To insure a proper seal, 1/2″ - 1″ ProPress® fittings require a minimum space between the fittings. Refer to chart on Page 11 for minimum distances. Preparing the Tube 1. If necessary, cut the desired length of tube using a tubing cutter. 2. Debur the tube inside and outside diameter using a rounded file or a deburring tool. 3. Clean the tube end of all dirt, oil and grease. Ridge Tool Company 7