Ridgid 100-B Owners Manual - Page 7

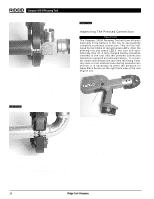

Inspecting The Compact, Pressing Tool and Jaw Sets

|

View all Ridgid 100-B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

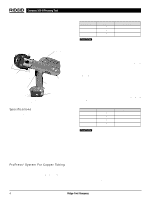

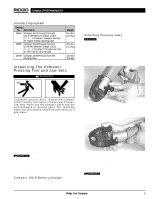

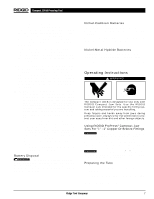

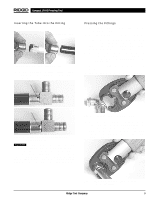

Compact 100-B Pressing Tool Standard Equipment Catalog No. Description 16953 Compact 100-B Pressing Tool with (2) Ni-MH Batteries, Charger (115V), 1/2″, 3/4″, 1″ ProPress® Compact Jaw Sets for Copper Tubing, Carrying Case 16988 Compact 100-B Pressing Tool with (2) Ni-MH Batteries, Charger (115V), 1/2″, 3/4″, 1″ PureFlow™ Compact Jaw Sets for PEX Tubing, Carrying Case 16948 Compact 100-B Pressing Tool with Carrying Case Weight 25.4 lbs. (11,5 kg.) 25.4 lbs. (11,5 kg.) 12.0 lbs (5.5 kg) Inspecting The Compact Pressing Tool and Jaw Sets WARNING replaced. Inspect charger for damage. Do not use charger if it has received a sharp blow, been dropped or otherwise damaged. Attaching Pressing Jaws CAUTION Only use RIDGID Jaw Sets. Use with the RIDGID jaw set intended for the specific fitting system and tubing material you are installing. Use of other jaw sets will result in an improper seal that could result in extensive property damage. 1. Make sure the battery is removed. 2. Pull the jaw set mounting pin to its most open position (Figure 2). To prevent serious injury, inspect the Compact 100-B Pressing Tool, battery charger and Compact Jaw Sets. Never use the Compact 100-B Jaw Set with damaged or missing parts. The following inspection procedures should be performed on a daily basis: 1. Make sure the Compact 100-B Pressing Tool battery is removed. 2. Inspect the tool housing and switch for damage. Check for damage such as cracks in the tool housing and exposed wires. 3. Inspect the jaw sets. If dirty, clean jaw sets. Refer to Maintenance Section for cleaning instructions. Failure to properly maintain jaws can result in an improper connection that can lead to extensive property damage. If any cracks are found, discard the damaged assemblies and obtain replacement. WARNING Always discard the entire assembly. Never replace individual components except for jaw return springs. Failure to replace the entire assembly may result in component failure and serious injury. 4. Clean any oil, grease or dirt from the tool handles. This reduces the risk of the tool slipping from your grip. Compact 100-B Battery Charger Inspect the power cord and plug for damage. If the cord or plug is damaged, do not use the charger until the cord is Figure 2 - Pulling The Jaw Set Mounting Pin Out 3. If pressing tool contains a jaw set, slide it out of the pressing tool. Figure 3 - Sliding Jaw Set Into Compact 100-B 4. Select the jaw set that corresponds to the tubing size and fitting system. Inspect the jaw set. If dirty, clean jaw sets. Refer to Maintenance Section for cleaning instructions. WARNING Failure to clean jaws can result in an im- proper connection that can lead to extensive property damage. If any cracks are found, discard the damaged jaw set and obtain replacement. Ridge Tool Company 5