Bernina Bernette 340 deco User Guide - Page 21

Embroidery stabilizers, Tear-away stabilizers, Cut-away stabilizers, Iron-on interfacing, Paper

|

View all Bernina Bernette 340 deco manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 21 highlights

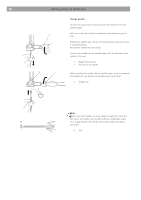

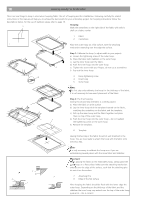

20 Getting Ready to Embroider Embroidery stabilizers Tear-away stabilizers • Similar to interfacing; tears like paper • one or more layers can be used • available in different weights • for more stability, apply to the wrong side of the fabric with temporary spray adhesive before hooping • carefully tear away excess stabilizer from the back of the embroidery after stitching • stabilizer will remain under larger embroidered areas Application: For all wovens and non-stretchables Cut-away stabilizers • one or more layers can be used • available in light- and heavyweight • for more stability, apply to the wrong side of the fabric with temporary spray adhesive before hooping • carefully cut away from the back of the embroidery after stitching • stabilizer will remain under larger embroidered areas Application: For all stretchable fabrics Iron-on interfacing • must be preshrunk by soaking in warm water • this is pressed (fused) to the wrong side of the fabric • iron-on interfacings are available in a variety of weights and should be selected to suit the fabric being used • removable iron-on interfacing is also available Application: To provide body and shape for fabrics onto which motifs will be placed. Use in conjunction with appropriate stabilizer Paper backed adhesive stabilizer • place stabilizer in hoop, paper side up • use a pointed object (e.g. scissors) to score the paper and remove it to reveal the self- adhesive surface • position the piece of fabric to be embroidered on the stabilizer Application: Intended for delicate fabrics such as jersey or silk, or hard to hoop fabrics such as velvets For pieces, sections and materials that can not be hooped Note: When using paper backed adhesive stabilizer make sure that there is no adhesive residue on needle, stitch plate and hook area. Spray adhesive • do not use spray adhesive near or directly at embroidery computer • use spray to stick stabilizer to wrong side of fabric for more stability • sparingly use spray adhesive and spray form a distance of 25-30cm to stabilizer • place fabric and sprayed stabilizer flat on each other and press together Application: On stretchable fabrics and knits to prevent distortion. Appliqué: exact securing of appliqués for embroidery. Smooth fabrics: to prevent shifting. Cutwork: to fix cut-out pieces on stabilizers, e. g. pockets on trousers, collars etc. For fabrics that easily crush or otherwise be marked by hooping: use spray adhesive on the stabilizer, hoop the stabilizer, then fix the sections to be embroidered onto the stabilizer.