Brother International XR1300 Users Manual - English - Page 104

While sewing, The sewing, machine does not, work., Fabric being, sewn with the, machine cannot,

|

View all Brother International XR1300 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 104 highlights

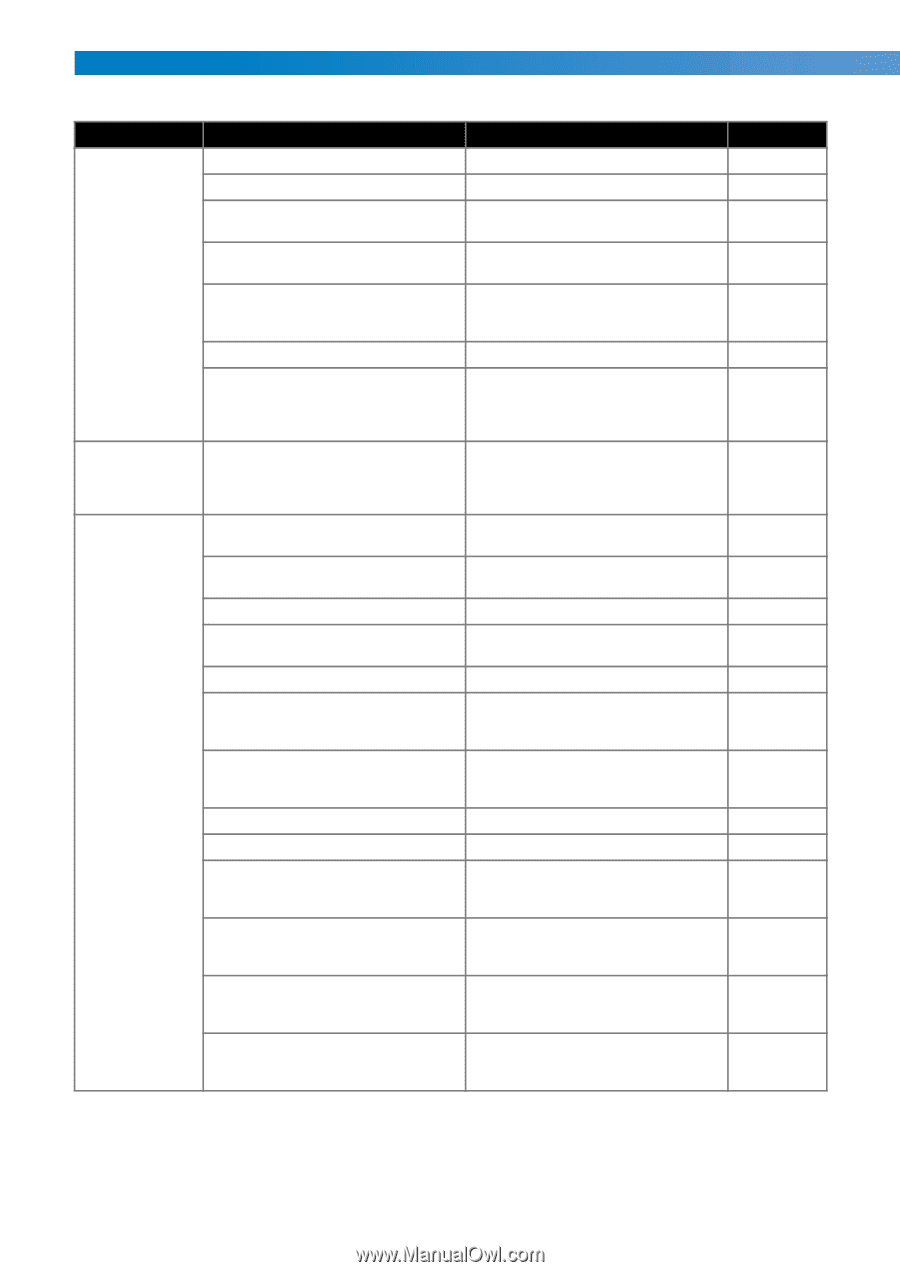

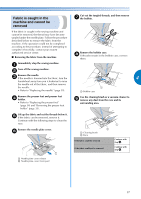

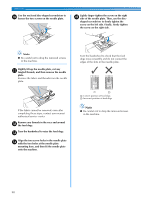

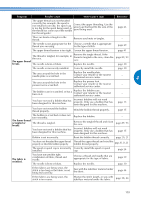

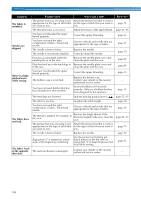

APPENDIX ■ While sewing Symptom Possible cause How to put it right Reference The machine is not plugged in. Plug the machine in. page 12 The main power switch is turned off. Turn on the main power switch. page 12 The bobbin winder shaft is pushed to Move the bobbin winder shaft to the the right. left. page 18, 19 The sewing You have not used the foot controller properly. Use the foot controller properly. machine does not The foot controller or the start/stop work. button was not pressed (for models equipped with the start/stop button). Press the foot controller or the start/ stop button. page 13 page 39 The presser foot lever is raised. Lower the presser foot lever. page 39 The start/stop button was pressed, even though the foot controller is connected. (for models equipped with the start/stop button) Do not use the start/stop button when the foot controller is connected. To use the start/stop button, disconnect the foot controller. page 39 Fabric being sewn with the machine cannot be removed. Thread is tangled below the needle plate. Lift up the fabric and cut the threads below it, and clean the race. page 97 The spool or spool cap is incorrectly Correctly install the spool or spool installed. cap. page 24 The upper thread was not threaded correctly. Correct the upper threading. page 23 The needle is incorrectly installed. Correctly install the needle. page 30 The needle clamp screw is loose. Use the disc-shaped screwdriver to firmly tighten the screw. page 31 The needle is bent or blunt. Replace the needle. page 30 You have not used the right combination of fabric, thread and needle. Choose a thread and needle that are appropriate for the type of fabric. page 29 The needle breaks. The presser foot you are using is not Attach the presser foot that is correct appropriate for the type of stitch that for the type of stitch that you want to you want to sew. sew. The upper thread tension is too tight. Loosen the upper thread tension. page 79 page 41 You are pulling the fabric too much. Lightly guide the fabric. - The area around the hole in the needle plate is scratched. Replace the needle plate. Contact your retailer or the nearest authorized service center. - The area around the hole in the presser foot is scratched. Replace the presser foot. Contact your retailer or the nearest authorized service center. - Replace the bobbin case. The bobbin case is scratched. Contact your retailer or the nearest - authorized service center. You have not used a bobbin that has been designed for this machine. Incorrect bobbins will not work properly. Only use a bobbin that has been designed for this machine. page 15 102