Brother International XR1300 Users Manual - English - Page 32

Checking the needle, Replacing the needle

|

View all Brother International XR1300 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 32 highlights

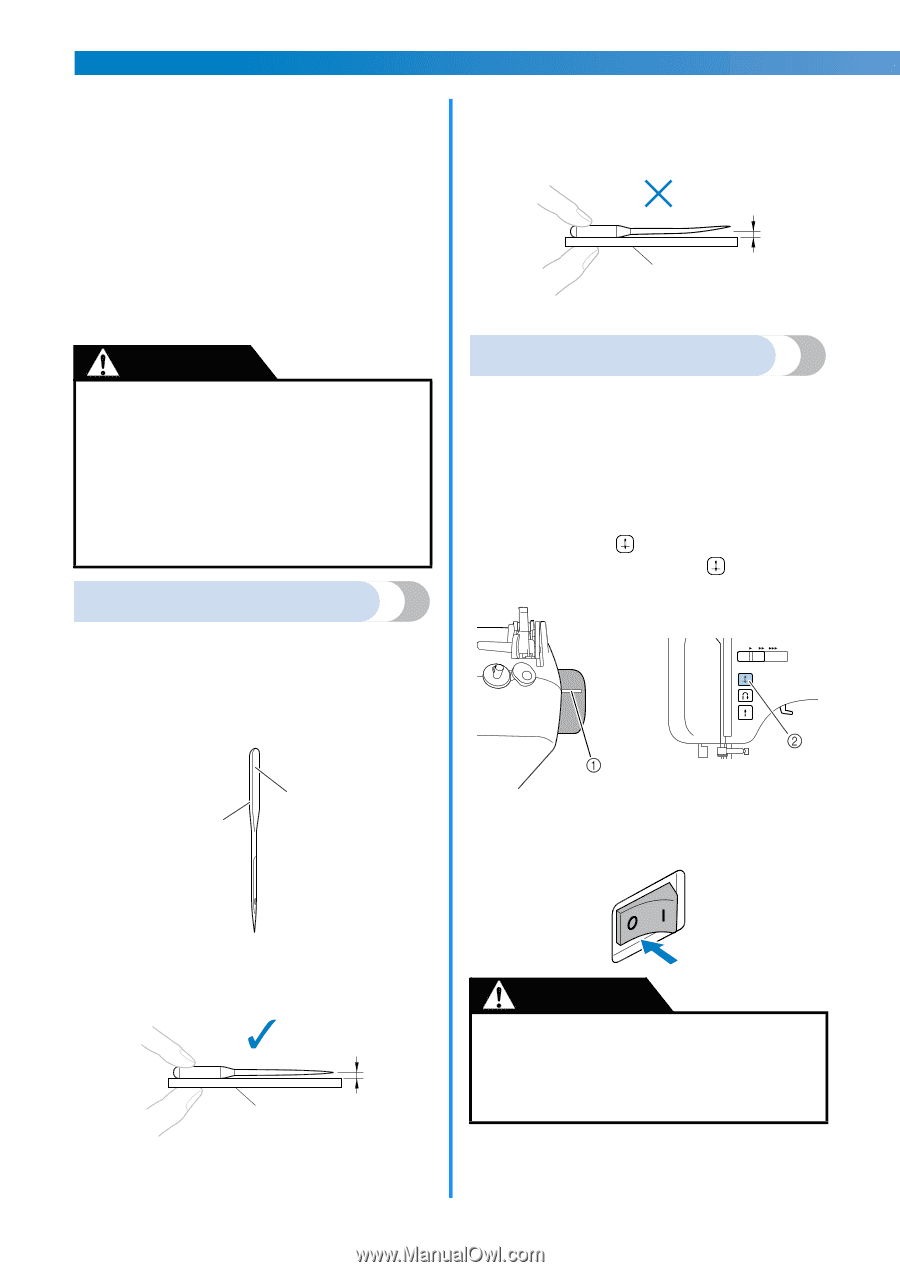

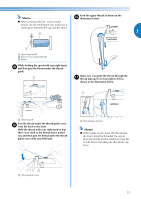

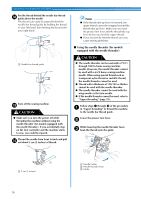

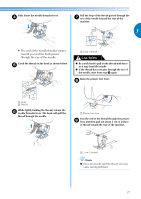

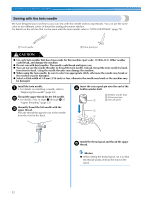

KNOWING YOUR SEWING MACHINE ■ Ball point needle Use the ball point needle when sewing on stretch fabrics or fabrics where skipped stitches easily occur. Use the ball point needle for best results when sewing patterns using monogramming foot "N". The factory recommended needle is "HG-4BR" (Organ). Schmetz needles "JERSEY BALL POINT" 130/705H SUK 90/14 may be used as a substitute. ■ Transparent nylon thread Use a 90/14 to 100/16 needle, regardless of the fabric or thread. CAUTION ● The appropriate fabric, thread and needle combinations are shown in the table on the previous page. If the combination of the fabric, thread and needle is not correct, particularly when sewing thick fabrics (such as denim) with thin needles (such as 65/9 to 75/11), the needle may bend or break. In addition, the stitching may be uneven or puckered or there may be skipped stitches. Checking the needle Sewing with a bent needle is extremely dangerous since the needle may break while the machine is being operated. Before using the needle, place the flat side of the needle on a flat surface and check that the distance between the needle and the flat surface is even. ■ Incorrect needle If the distance between the needle and the flat surface is not even, the needle is bent. Do not use a bent needle. 1 a Flat surface Replacing the needle Replace the needle as described below. Use the disc-shaped screwdriver and a needle that has been determined to be straight according to the instructions in "Checking the needle". Raise the needle by turning the handwheel a toward you (counterclockwise) so that the mark on the wheel points up. (With models equipped with (needle position button), raise the needle by pressing once or twice.) or 1 2 a Mark b Needle position button Turn off the sewing machine. b a Flat side b Needle type marking ■ Correct needle 1 a Flat surface 30 CAUTION ● Before replacing the needle, be sure to turn off the sewing machine, otherwise injuries may occur if the foot controller or the start/ stop button is accidentally pressed and the machine starts sewing.