Kenmore HE2t User Guide - Page 79

Diagnostics & Troubleshooting

|

View all Kenmore HE2t manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 79 highlights

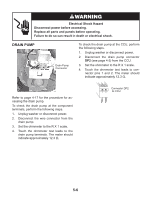

DIAGNOSTICS & TROUBLESHOOTING DIAGNOSTICS DIAGNOSTIC GUIDE Before servicing, check the following: • Make sure there is power at the wall outlet. • Has a household fuse blown or circuit breaker tripped? Time delay fuse? • Are both hot and cold water faucets open and water supply hoses unobstructed? • All tests/checks should be made with a VOM or DVM having a sensitivity of 20,000 ohms per volt DC or greater. • Check all connections before replacing components. Look for broken or loose wires, failed terminals, or wires not pressed into connections far enough. • A potential cause of a control not functioning is corrosion on connections. Observe connections and check for continuity with an ohmmeter. • Connectors: Look at top of connector. Check for broken or loose wires. Check for wires not pressed into connector far enough to engage metal barbs. • Resistance checks must be made with power cord unplugged from outlet, and with wiring harness or connectors disconnected. 6-1