2015 Kawasaki KX250F Owners Manual - Page 76

2015 Kawasaki KX250F Manual

Page 76 highlights

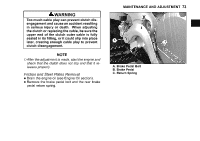

MAINTENANCE AND ADJUSTMENT 75 • Remove the friction and steel plates. Steel Plate Thickness Measurement Standard 1.5 ∼ 1.7 mm (0.059 ∼ 0.067 in.) Service Limit 1.4 mm (0.055 in.) j A. Friction Plate B. Steel Plate Friction and Inspection Steel Plates Wear/Damage inspect the friction and steel plates to see • Visually if they show any signs of seizure, or uneven wear. any plates show signs of damage, replace all • If friction plates and steel plates as a set. the thickness of the friction and steel • Measure plates with vernier calipers. they have worn past the service limit, replace • If them with new ones. Friction Plate Thickness Measurement Standard 2.72 ∼ 2.88 mm (0.107 ∼ 0.113 in.) Service Limit 2.5 mm (0.10 in.) A. Thickness B. Friction Plate Friction and Steel Plate Warp Inspection each friction plate and steel plate on a sur• Place face plate, and measure the amount of friction • plate and steel plate warp with a thickness gauge (i.e., the gap between the surface plate and each friction plate or steel plate). If any plate is warped over the service limit, replace it with a new one.