Brother International BES-963 Instruction Manual - English - Page 30

Brother International BES-963 Manual

|

View all Brother International BES-963 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 30 highlights

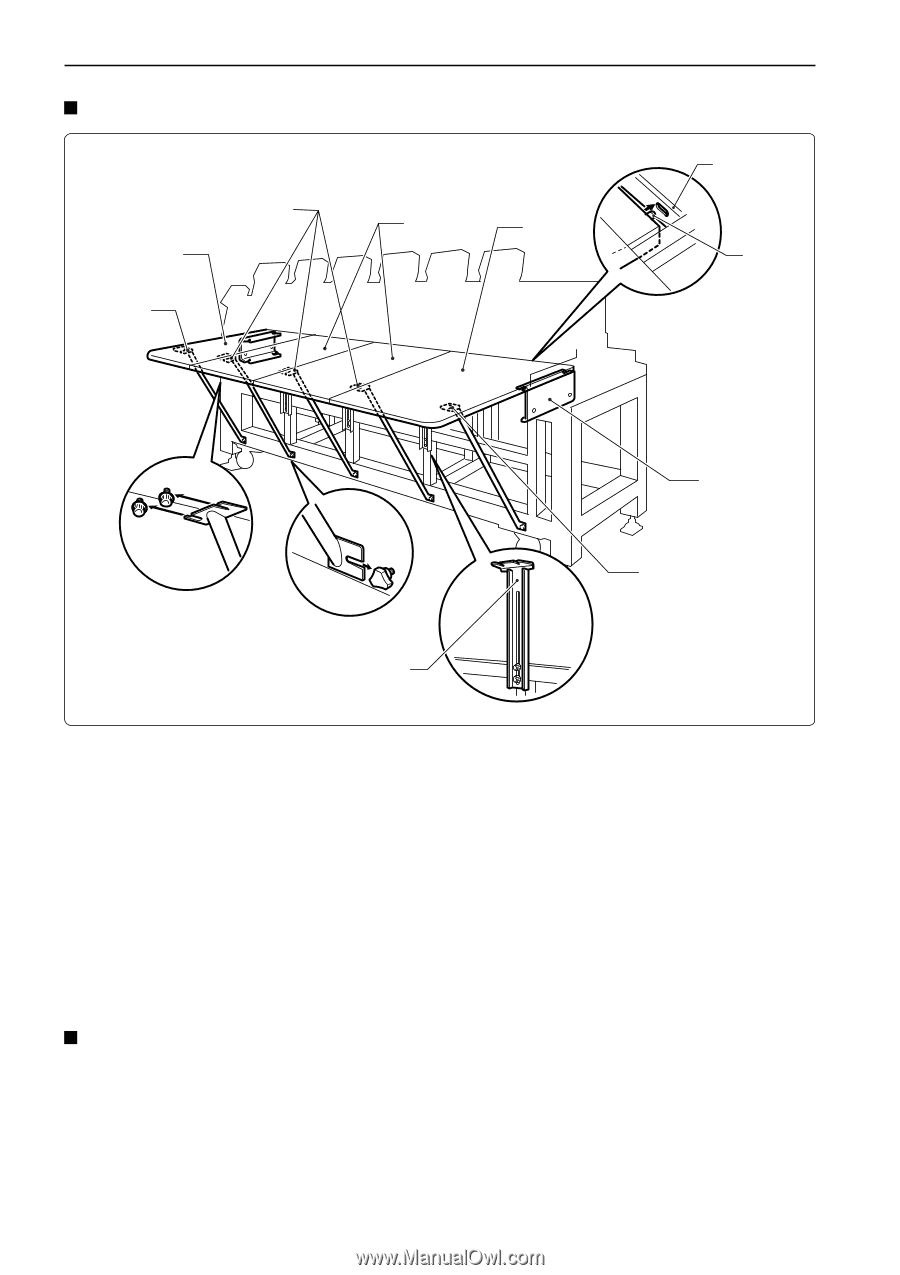

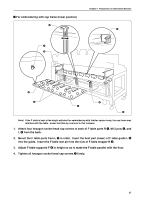

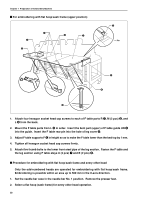

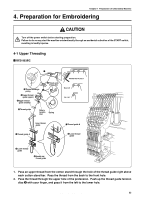

Chapter 1 Preparation of Embroidery Machine For embroidering with flat hoop/sash frame (upper position) u e i w q t Pin r i y 1. Attach four hexagon socket head cap screws to each of F table parts R q, M (2 pcs) w, and L e from the back. 2. Mount the F table parts from L e in order. Insert the bent part (upper) of F table guide UN r into the guide. Insert the F table rear pin into the hole of leg cover t. 3. Adjust F table supports F y in height so as to make the F table lower than the bed top by 1 mm. 4. Tighten all hexagon socket head cap screws firmly. 5. Attach five thumb bolts to the lower front steel pipe of the leg section. Fasten the F table and the leg section using F table stays A (3 pcs) u and B (2 pcs) i. Procedure for embroidering with flat hoop/sash frame and every other head Only the odd-numbered heads are operated for embroidering with flat hoop/sash frame. Embroidering is possible within an area up to 500 mm in the X-axis direction. 1. Set the needle bar case in the needle bar No. 1 position. Remove the presser feet. 2. Select a flat hoop (sash frame) for every other head operation. 28 BES-963BC • BES-1263BC