Brother International CE-5500/CE-5500PRW Operation Manual - Page 28

Thread tension

|

View all Brother International CE-5500/CE-5500PRW manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 28 highlights

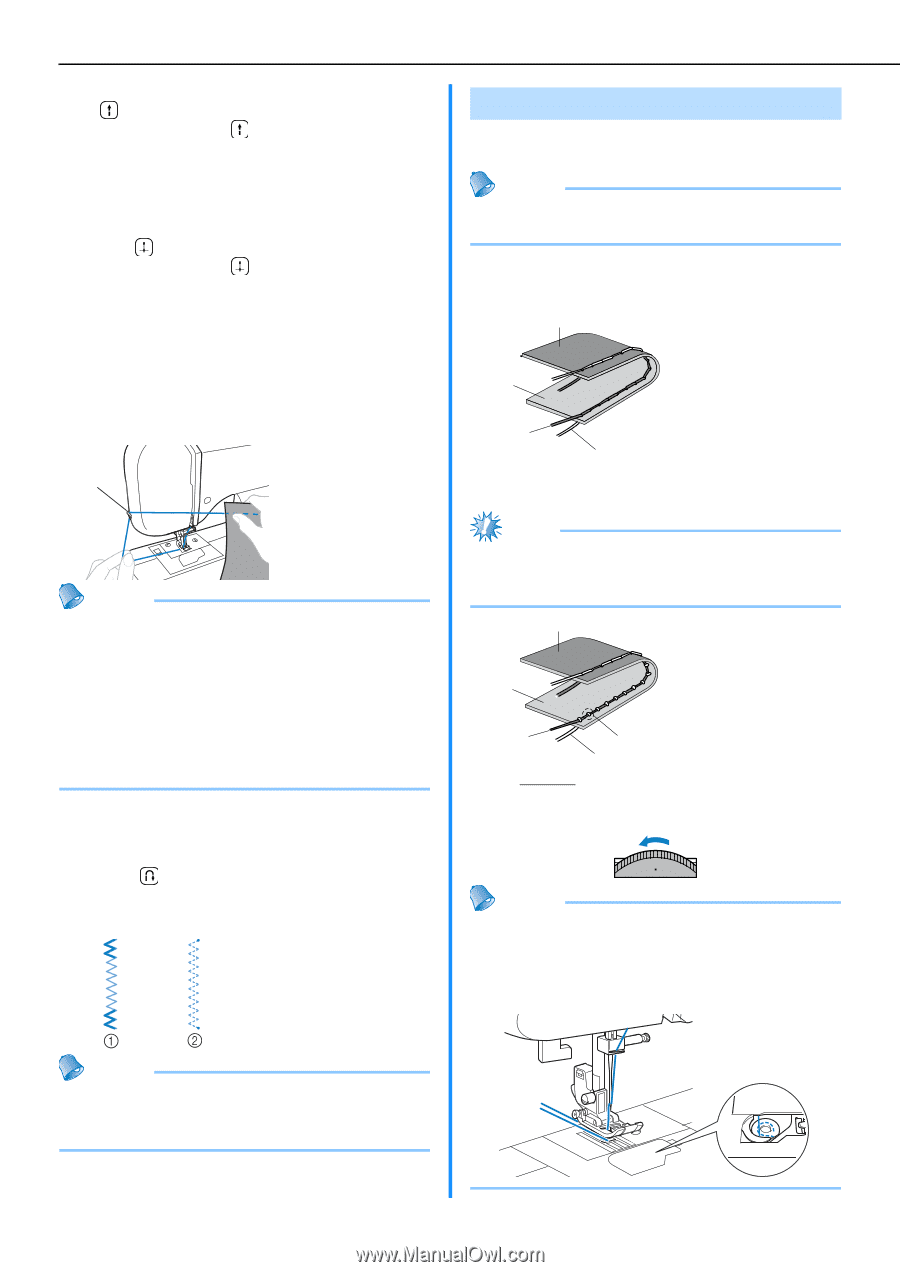

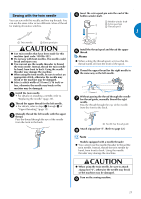

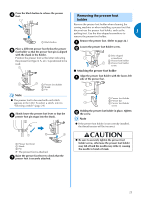

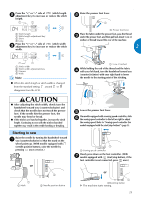

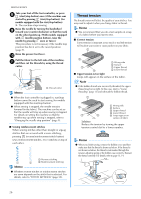

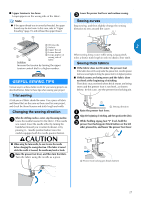

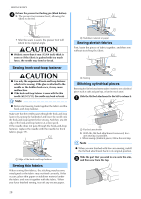

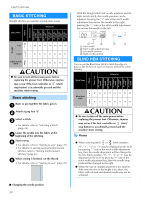

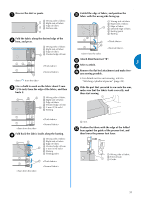

SEWING BASICS Take your foot off the foot controller, or press h (start/stop button) once (if the machine was started by pressing (start/stop button)) (for models equipped with the start/stop button). The machine stops sewing. Raise the needle by turning the handwheel i toward you (counterclockwise) so that the mark on the wheel points up. (With models equipped with (needle position button), raise the needle by pressing once or twice.) This procedure is not necessary if the needle stop position has been set to the raised position (page 9). Raise the presser foot lever. j Pull the fabric to the left side of the machine, k and then cut the threads by using the thread cutter. 1 a Thread cutter Memo ● When the foot controller is plugged in, start/stop button cannot be used to start sewing (for models equipped with the start/stop button). ● When sewing is stopped, the needle remains lowered (in the fabric). The machine can be set so that the needle will stay up when sewing is stopped. For details on setting the machine so that the needles stay up when sewing is stopped, refer to "Changing the needle stop position" (page 9). ■ Sewing reinforcement stitches When sewing stitches other than straight or zigzag stitches that are secured with reverse stitching, pressing (reverse/reinforcement stitch button) sews reinforcement stitches, 3 to 5 stitches on top of each other. a Reverse stitching b Reinforcement stitching Memo ● Whether reverse stitches or reinforcement stitches are sewn depends on the stitch that is selected. For details, refer to "STITCH SETTINGS" (page 50). Thread tension The thread tension will affect the quality of your stitches. You may need to adjust it when you change fabric or thread. Memo ● We recommend that you do a test sample on scrap of a fabric before you start to sew. ■ Correct tension Correct tension is important as too much or too little tension will weaken your seams or cause puckers on your fabric. 1 2 3 4 a Wrong side b Surface c Upper thread d Lower thread ■ Upper tension is too tight Loops will appear on the surface of the fabric. Note ● If the bobbin thread was incorrectly threaded, the upper thread may be too tight. In this case, refer to "Lower threading" (page 13) and rethread the bobbin thread. 1 2 3 a Wrong side b Surface c Upper thread d Lower thread 5 e Loops appear on 4 surface of fabric Solution Reduce the tension by turning the upper tension-control dial to a lower number. 54 3 Memo ● When you finish sewing, remove the bobbin cover and then make sure that the thread is shown as below. If the thread is not shown as below, the thread is not inserted through the tension-adjusting spring of the bobbin case correctly. Reinsert the thread correctly. For details, refer to page 13, 14. 26