Brother International Innov-is 40e Operation Manual - Page 98

Incorrect thread tension

|

View all Brother International Innov-is 40e manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 98 highlights

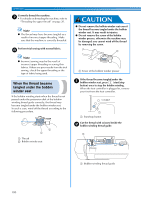

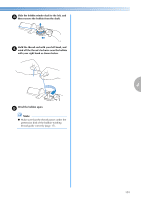

APPENDIX Incorrect thread tension ■ Symptoms • Symptom 1: The lower thread is visible from the upper side of the fabric. • Symptom 2: The upper thread appears as a straight line on the upper side of the fabric. • Symptom 3: The upper thread is visible from the lower side of the fabric. • Symptom 4: The lower thread appears as a straight line on the lower side of the fabric. • Symptom 5: The stitching on the lower side of the fabric is loose or has slack. ❏ Symptom 1 ❏ Symptom 3 a Lower side of fabric b Lower thread visible from upper side of fabric c Upper thread d Upper side of fabric e Lower thread f Upper thread visible ■ Cause/remedy/check details from lower side of fabric ❏ Cause 1 The machine is not correctly threaded. The lower threading is incorrect. Return the thread tension dial to "4", and then refer to "Upper thread tightened up" on page 93 to correct the threading. Note ● If the upper threading and lower threading are incorrect, the thread tension cannot be adjusted correctly, even by turning the thread tension dial. Check the upper threading and lower threading first, and then adjust the thread tension. The upper threading is incorrect. Return the thread tension dial to "4", and then refer to "Tangled thread on wrong side of fabric" on page 94 to correct the upper threading. ❏ Cause 2 • When the lower thread is visible from the upper side of the fabric. Turn the thread tension dial to a lower number (toward the left). (Loosen the thread tension.) A needle and thread appropriate for the fabric are not being used. The sewing machine needle that should be used depends on the type of fabric sewn and the thread thickness. If a needle and thread appropriate for the fabric are not being used, the thread tension will not be • When the upper thread is visible from the lower side of the fabric. Turn the thread tension dial to a higher number (toward the right). (Tighten the thread tension.) adjusted correctly, causing wrinkles in the fabric or skipped stitches. • Refer to "Needle types and their uses" on page 28 to check that a needle and thread appropriate for the fabric are being used. ❏ Cause 3 An appropriate setting on the thread tension dial is not selected. Turn the thread tension dial to select an appropriate thread tension. The appropriate thread tension differs according to the type of fabric and thread being used. * Adjust the thread tension while test sewing on a piece of scrap fabric that is the same as that used in your project. 96