Konica Minolta C83hc High Chroma GBC PUNCH G2 User Manual - Page 4

Safety messages, Service, PUNCH G2, Service, Diesets, Duty Cycle and Product Positioning, Operating

|

View all Konica Minolta C83hc High Chroma manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 4 highlights

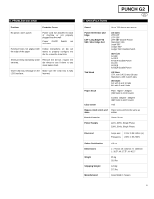

Safety messages MAIN CORDSET SELECTION (THE FOLLOWING NOTE ONLY APPLIES ONLY TO THE UNITS RATED 230V 50Hz, AND LOCATED IN THE EUROPEAN UNION) CAUTION: WHEN CHOOSING A DETACHABLE LINE CORD FOR USE WITH YOUR PUNCH G2, ALWAYS FOLLOW THE FOLLOWING PRECAUTIONS The cordset consists of three parts: the attachment plug, the cord and the appliance inlet. Each of these components must have European regulatory safety approvals. The following minimum electrical ratings for the specific cordset are published for safety purposes. DO NOT USE CORDSETS THAT DO NOT MEET THE FOLLOWING MINIMUM ELECTRICAL REQUIREMENTS. PLUG: 3 amperes, 250 volts, 50/60 Hz, Class 1, 3 conductor, European safety approved. CORD: Type H05VV-F3G0.75, Harmonized (< HAR >). The "< >" symbols indicate cord approved according to appropriate European standard (NOTE: "HAR" may be substituted for approval mark of European safety agency that approved the cord. An example would be "< VDE >"). APPLIANCE CONNECTOR: 3 amperes, 250 volts, 50/60 Hz, European safety approved, Type IEC 320. The cordset shall not exceed 3 meters in length. A cordset with component electrical ratings greater than the minimum specified electrical ratings may be substituted. Service, PUNCH G2 Do not attempt to service your PUNCH G2 yourself. Contact an authorized service representative for any required repairs or major maintenance for your PUNCH G2. DO NOT REMOVE THE MACHINE'S COVER. There are NO user-serviceable parts inside the machine in order to avoid potential personal injury and/or damage to property or the machine itself. Service, Diesets Every dieset is thoroughly oiled at the factory prior to shipping. Please note that it is normal for oil to be present on the first few punched sheets. During normal use this oil will be exhausted and should be replaced. As part of regular maintenance, each dieset should be oiled after approximately 250K punch cycles or sooner. GBC recommends use of brand 3-IN-ONE oil as it is readily available. Other light machine oils can also be used. To oil the dieset, refer to Section 8- Die Set User manual. Please note that it is normal for oil to be present on the first set of sheets punched after oiling the dieset. After approximately 25 to 50 sheets oil will no longer be found on the punched sheet. At this time the PUNCH G2 can be utilized for punching of print jobs. Refer to Section 8 - Die Set User manual for detailed cleaning instructions of the crease die. See Section 8 PUNCH G2 Dieset Manual for further instructions on servicing the Diesets. Safety messages FCC NOTE (THE FOLLOWING NOTE ONLY APPLIES TO THE UNITS RATED 115V 60Hz.) This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful PUNCH G2 EN interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the Operation Manual, may cause harmful interference with radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his/her own expense. CAUTION: CHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED BY GENERAL BINDING CORPORATION COULD VOID YOUR AUTHORITY TO OPERATE THE EQUIPMENT. 2. INTRODUCTION Thank you for purchasing the PUNCH G2. It is a versatile production system that will enable you to punch documents for a variety of binding styles by means of a simple die change. It has also been designed for easy operation. The PUNCH G2 is an innovative solution for punching paper and offers the following design features: Quick-change die sets that can be interchanged without any tools. All PUNCH G2 die sets include an Identification Label providing the user with the hole pattern and name. Convenient storage area for two extra Die Sets located above the sheet bypass. Duty Cycle and Product Positioning The GBC PUNCH G2 provides a flexible, cost effective punching solution for light to medium level punching production environments. It is designed for production print users that typically punch their documents at an average of 20-30% of their overall workflow. For customers that run continuous punching for long runs of over 4 hours, performance may vary or degrade due to a wide range of media weights and environmental conditions that can occur. Maximum Recommended Monthly Volume - The maximum recommended monthly punch volume should NOT exceed 400,000. Operating Die Set Supplies Dies are considered consumables and when worn, must be replaced since sharpening is not possible. Each die set has a 90-day warranty from the date of purchase. The warranty is void if the die is used beyond its specifications. Punch die life will be maximized if oiled every 100,000 punch cycles (see Dieset Service for details) Die sets have an expected use life of 750,000 punches using 20 lb/75 gsm paper. This is a minimum life expectation only. Die life is NOT guaranteed due to a wide range of media weights and environmental conditions that the dies may endure. If you are going to be punching extended runs that exceed the die use life, it is strongly recommended that you have sufficient numbers of the appropriate die sets on hand to continue with minimal downtime. 4