Sub-Zero 427R Wine Storage Installation Instructions - Page 37

Model WS-30 Installation, Anti-Tip Bracket Installation

|

View all Sub-Zero 427R manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 37 highlights

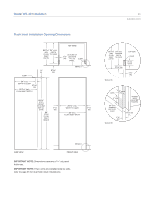

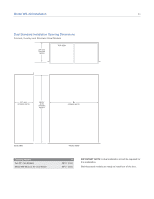

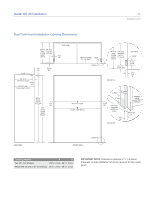

Model WS-30 Installation 37 subzero.com Anti-Tip Bracket Installation To prevent the unit from tipping forward and provide a stable installation, the unit must be secured in place with the anti-tip brackets provided. IMPORTANT NOTE: Placement of the anti-tip brackets is critical to a stable installation. Failure to properly position the anti-tip brackets will prevent them from engaging the unit. The two anti-tip brackets must be installed exactly 24" (610) from the front of the rough opening to the back of the brackets and a minimum of 4" (102) from the sides of the rough opening. This depth will increase to 263/16" (665) for a flush inset installation based on 3/4" (19) deep decorative panels. Proper placement will ensure that the anti-tip brackets engage the anti-tip bar at the back of the unit. To properly secure the anti-tip brackets for a stable installation, use all anti-tip bracket hardware as instructed for wood or concrete floors. IMPORTANT NOTE: For either wood or concrete floor applications, if the #12 x 21/2" screws do not hit a wall stud or the wall plate in any of the back holes of the brackets, use the provided #8-18 x 11/4" PH truss HD screws and #12 flat washers with the nylon zip-it wall anchors. IMPORTANT NOTE: In some installations the subflooring or finished floor may necessitate angling the screws used to fasten the anti-tip brackets to the back wall. Make sure there are no electrical wires or plumbing in the area which the screws could penetrate. Anti-Tip Bracket Hardware 2 Anti-tip brackets 12 #12 x 21/2" PH pan HD zinc screws 4 3/8"-16 x 33/4" wedge anchors 12 #12 flat washers 4 #8-18 x 11/4" PH truss HD screws 4 Nylon zip-it wall anchors