Sub-Zero 427R Wine Storage Installation Instructions - Page 9

Model 424fsg-wood Floors, Model 424fsg-concrete Floors, Install Concrete Wedge Anchors

|

View all Sub-Zero 427R manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

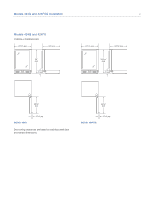

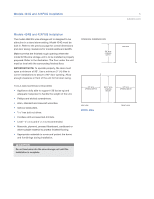

Models 424G and 424FSG Installation 9 subzero.com Anti-Tip Bracket Installation MODEL 424FSG-WOOD FLOORS Use the four #12 x 21/2" wood screws and the four 1/4" flat washers provided. Drill pilot holes 3/16" (5) diameter maximum, and be sure that the screws penetrate through the flooring material and into the wall plate a minimum of 3/4" (19). Be sure that the screws hold tight. Refer to the illustration below. MODEL 424FSG-CONCRETE FLOORS Use the two 3/8" x 33/4" concrete wedge anchors, two #12 x 21/2" wood screws and two 1/4" flat washers provided. Be sure that the anchors and screws hold tight. Refer to the illustration below. IMPORTANT NOTE: In some installations the subflooring or finished floor may require angling the wood screws used to fasten the anti-tip bracket to the back wall. Make sure that there are no electrical wires in the area which the screws could penetrate. INSTALL CONCRETE WEDGE ANCHORS: 1) Drill a 3/8" (10) diameter hole any depth exceeding the minimum embedment. Clean the hole or continue drilling additional depth to accommodate drill fines. Use a carbide drill bit manufactured within ANSI B94.12-77. 2) Assemble the washer and nut flush with the end of anchor to protect threads. Drive the anchor through the material to be fastened until the washer is flush with the surface material. 3) Expand the anchor by tightening the nut 3-5 turns past hand-tight position or to 25 foot-pounds of torque. Always wear safety glasses and use other necessary protective devices or apparel when installing or working with anchors. Anchors are not recommended for use in lightweight masonry material such as block or brick, or for use in new concrete which has not had sufficient time to cure. The use of core drills is not recommended to drill holes for the anchors. 24" (610) CL 12 3/16" (310) 12 3/16" (310) FINISHED FLOORING UNDERLAYMENT 24" (610) CL 12 3/16" (310) 12 3/16" (310) FINISHED FLOORING UNDERLAYMENT WALL PLATE SUBFLOORING WOOD FLOOR 11/2" min (38) WALL PLATE SUBFLOORING CONCRETE FLOOR Wood floors. Concrete floors.