Motorola V186 User Manual - Page 5

ACE3600 System Overview, SCADA, Manager

|

View all Motorola V186 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

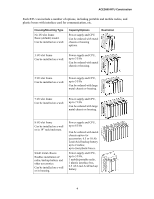

INPUTS OTPUTS ACE3600 System Overview The purpose of ACE3600 system is typically to provide some degree of automatic operation to a new or existing customer process. The process may be found in water pump stations, sewage lift stations, communication system monitoring, security, public notification control, electrical substation monitoring, distribution automation, demandside management, automated meter reading, or other applications. This automation is provided by a combination of hardware. • Remote Terminal Unit (RTU): The field sites are equipped with ACE3600 RTUs that collect data from on-site sensors, add data from off-site sources, and use this data aggregate to make decisions regarding how the process is operating. Changes to the local process may be made; messages may be initiated that send data elsewhere to influence the operation of off-site equipment or to advise the SCADA Manager of some important change. • Communications: RTU Communication CoSmymstuenmication System The multiple sites in the system may communicate among themselves by utilizing a variety of communication choices: IP STS FEP networks, two-way conventional, trunked, or data radio or any other communication network. MDLC, the main communication protocol employed by ACE3600, is based on the seven-layer OSI recommendation, SCADA Manager and is designed to be totally functional on variety of communication media. MDLC includes a store-&-forward capability that permits different communication media links to be incorporated into the total system, i.e. conventional radio and trunked radio and microwave radio and LAN all interconnected by ACE3600 into a single communication system. Data may be passed from any site to any other site in the system (peer-to-peer) either directly or by multiple hops through intermediate ACE3600 sites. This peer-to-peer communication capability enables system designs that use a distributed-intelligence operating philosophy; central-intelligence-only systems may also be implemented if the load on the communication system permits it. 1