Samsung SCX4521F Service Manual - Page 30

Printing Process Part, Line Interface Part, Engine Paper Feeding, OPC Drum, Photo Diode - scx parts

|

UPC - 635753616040

View all Samsung SCX4521F manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 30 highlights

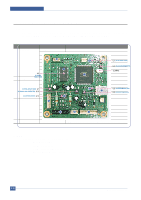

System Overview 3.2.4 Printing Process Part Printing Process part is made of PC-Interface part, PVC(Priter Video Controller), LSU control part, High Voltage control part and Fuser Unit control part. PC-interface core is included in the Chorus2 ASIC and controls the PCinterface. LSU control part controls the LSU polygon motor, Laser diode, video data output so thatthe printing image can be made up on the OPC Drum. 3.2.5 Line Interface Part Line interface part helps the machine connect to the PSTN or PABX Line and is made of almost primary circuit. Its main function is Line connection, Line state monitoring and TAD interface that enables a extension telephone or TAD machine to connect to the SCX-4521F machine. OPC Drum 3.2.6 EPnhgotionDeioPdaeper Feeding 1) Feeding Type : MP Cassette Type 2) Feeding Standard : Center Loading 3) Feeding Qty : Cassette 150 sheets (75g/ , 20lb paper standard) 4) 1 sheet (Paper, OHP, Envelope etc.) 5) Separating Type: Cassette - Friction Pad Type 6) MLDanDuarlivTerar yci:rc1itsheet 7) Driver Type : Driving by Gearing from Main Motor 8) Pick_up Roller Driver : Solenoid P9ro)tPeicctkourppRanoellelr Rubber MLaDte(Lriaals:eErPDDioMd+eI)R =1.3 or more 10) Pick up Velocity : 94.8731mm/Sec (Process : 93.0667mm/sec) 11) Paper detecting Sensor : Photo Sensor 12) Paper Size Sensor : None 13) Paper Separating Pad Material : NBB 52 °, =0.8~1.2 14) Separating Pad Pressure : TBD 150 gf 15) Pick_up Roller RPM : 47.683 RPM 16) Feeding Pressure (Same as Transfer Roller) 17) Paper Exit Type : Face Down 18) Feed Roller Force : TBD Kg.f or more. 19) Spring Feed Tensile Force : TBD gf 20) Feed roller Velocity : mm/sec 21) Feed Roller Material 22) Exit Sensor : Photo Sensor Polygon Mirror Polygon Motor Motor Driver 3-8 Service Manual Samsung Electronics