Brother International BAS-416A Instruction Manual - English - Page 111

interruption

|

View all Brother International BAS-416A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 111 highlights

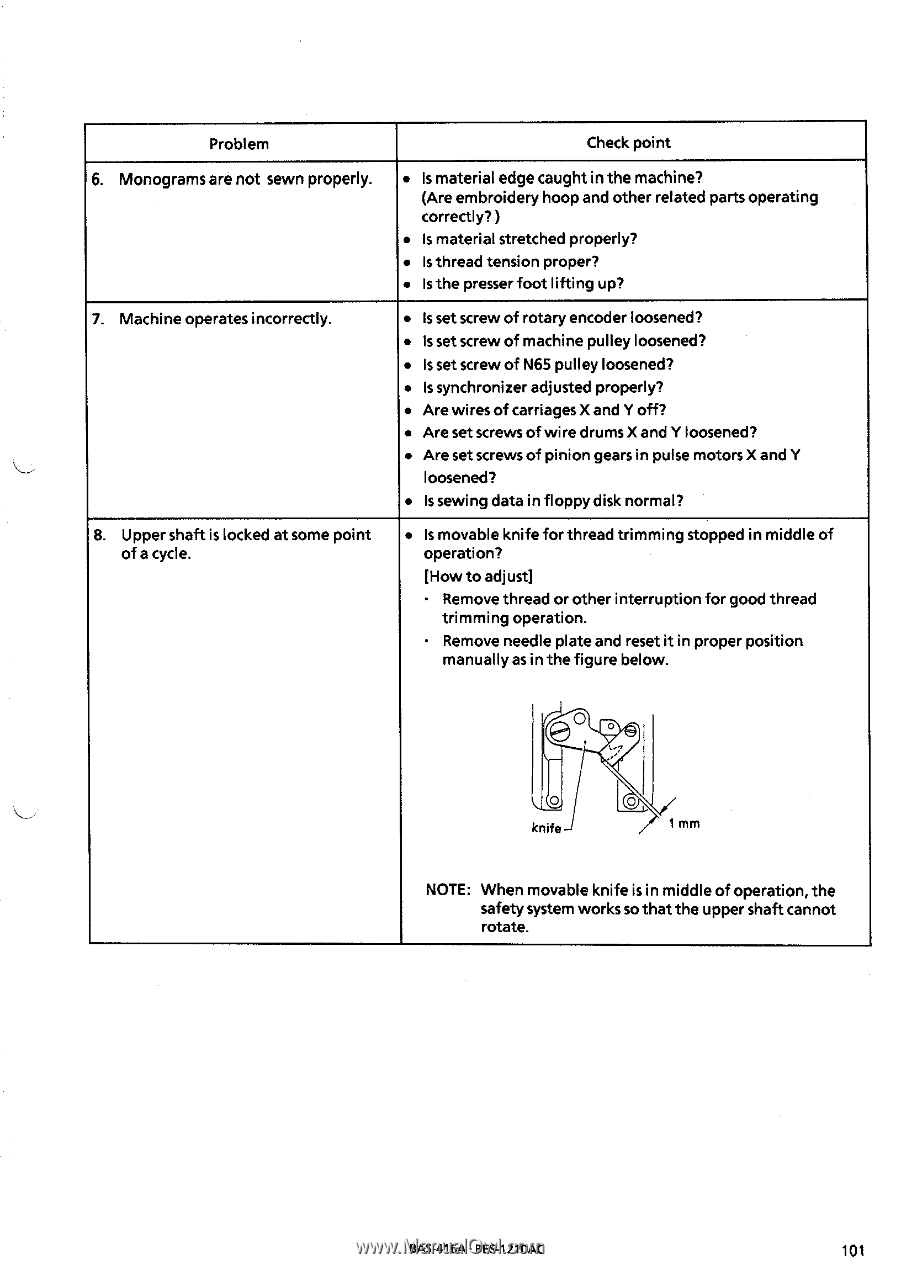

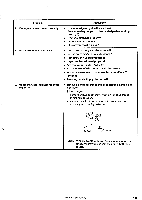

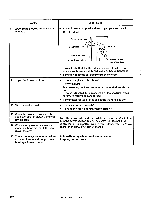

Problem 6. Monograms are not sewn properly. 7. Machine operates incorrectly. 8. Upper shaft is locked at some point of a cycle. Check point • Is material edge caught in the machine? (Are embroidery hoop and other related parts operating correctly? ) • Is material stretched properly? • Is thread tension proper? • Is the presser foot lifting up? • Is set screw of rotary encoder loosened? • Is set screw of machine pulley loosened? • Is set screw of N65 pulley loosened? • Is synchronizer adjusted properly? • Are wires of carriages X and Y off? • Are set screws of wire drums X and Y loosened? • Are set screws of pinion gears in pulse motors X and Y loosened? • Is sewing data in floppy disk normal? • Is movable knife for thread trimming stopped in middle of operation? [How to adjust] • Remove thread or other interruption for good thread trimming operation. • Remove needle plate and reset it in proper position manually as in the figure below. O O o knife- o 1 mm NOTE: When movable knife is in middle of operation, the safety system works so that the upper shaft cannot rotate. BAS-416A • BES-1210AC 101