Brother International HL-6180DW User's Guide - English - Page 11

Envelopes, Types of envelopes to avoid, Important - laser printer

|

View all Brother International HL-6180DW manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

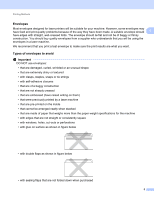

Printing Methods Envelopes 1 Most envelopes designed for laser printers will be suitable for your machine. However, some envelopes may have feed and print-quality problems because of the way they have been made. A suitable envelope should 1 have edges with straight, well-creased folds. The envelope should lie flat and not be of baggy or flimsy construction. You should buy quality envelopes from a supplier who understands that you will be using the envelopes in a laser machine. We recommend that you print a test envelope to make sure the print results are what you want. Types of envelopes to avoid 1 Important DO NOT use envelopes: • that are damaged, curled, wrinkled or an unusual shape • that are extremely shiny or textured • with clasps, staples, snaps or tie strings • with self-adhesive closures • that are of a baggy construction • that are not sharply creased • that are embossed (have raised writing on them) • that were previously printed by a laser machine • that are pre-printed on the inside • that cannot be arranged neatly when stacked • that are made of paper that weighs more than the paper weight specifications for the machine • with edges that are not straight or consistently square • with windows, holes, cut-outs or perforations • with glue on surface as shown in figure below • with double flaps as shown in figure below • with sealing flaps that are not folded down when purchased 5