Dewalt DHS790AT2 Instruction Manual - Page 19

Special Cuts

|

View all Dewalt DHS790AT2 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

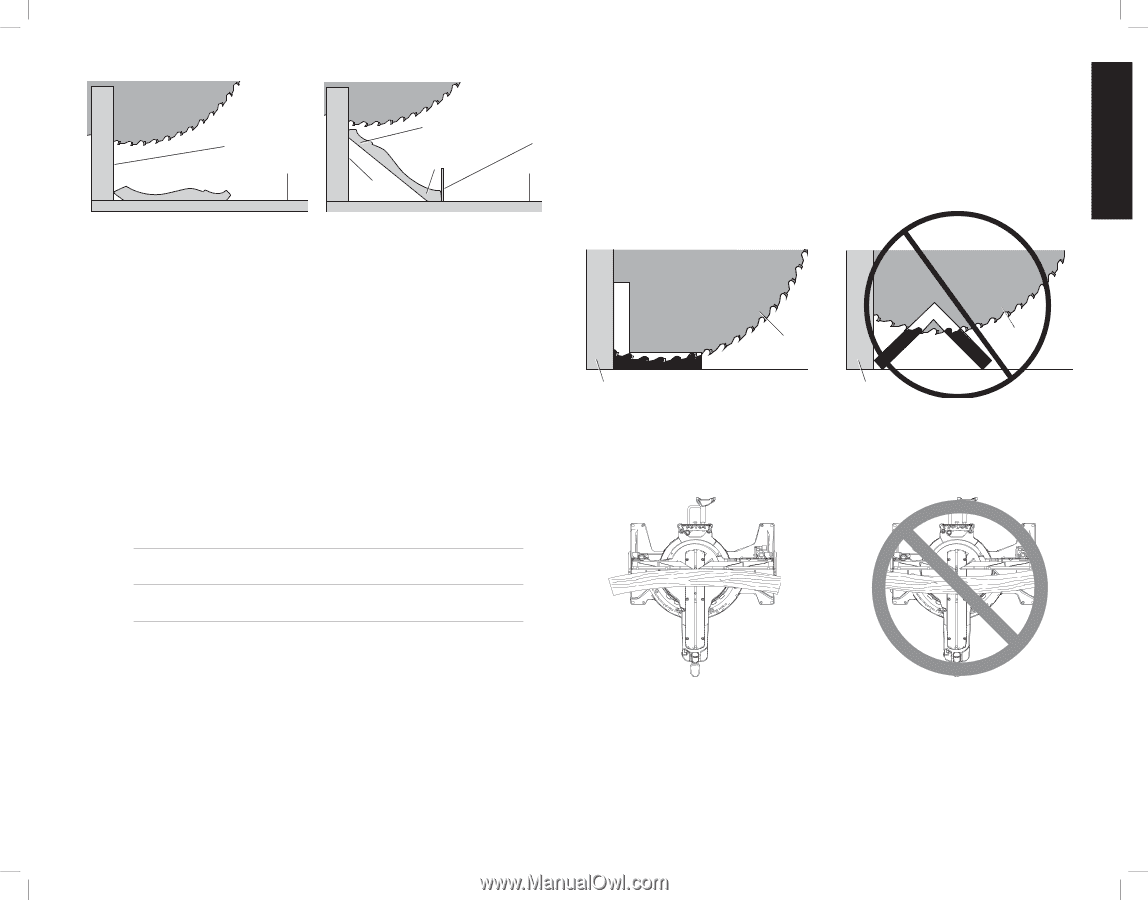

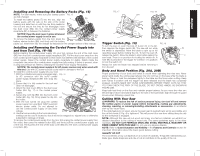

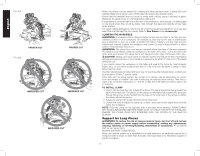

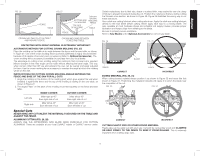

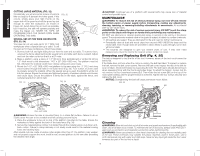

English FIG. 26 FIG. 27 FENCE TABLE BOTTOM SIDE OF MOLDING TOP SIDE OF MOLDING DW7084 CROWN MOLDING FENCE TABLE FENCE CROWN MOLDING FLAT ON TABLE AND AGAINST FENCE CROWN MOLDING BETWEEN FENCE AND TABLE PRETESTING WITH SCRAP MATERIAL IS EXTREMELY IMPORTANT! ALTERNATIVE METHOD FOR CUTTING CROWN MOLDING (FIG. 27) Place the molding on the table at an angle between the fence and the saw table, as shown in Figure 27. Use of the crown molding fence accessory (DW7084) is highly recommended because of its degree of accuracy and convenience (Refer to Optional Accessories). The crown molding fence accessory is available for purchase from your local dealer. The advantage to cutting crown molding using this method is that no bevel cut is required. Minute changes in the miter angle can be made without affecting the bevel angle. This way, when corners other than 90º are encountered, the saw can be quickly and easily adjusted for them. Use the crown molding fence accessory to maintain the angle at which the molding will be on the wall. INSTRUCTIONS FOR CUTTING CROWN MOLDING ANGLED BETWEEN THE FENCE AND BASE OF THE SAW FOR ALL CUTS 1. Angle the molding so the bottom of the molding (part which goes against the wall when installed) is against the fence and the top of the molding is resting on the saw table, as shown in Figure 27. 2. The angled "flats" on the back of the molding must rest squarely on the fence and saw table. INSIDE CORNER OUTSIDE CORNER Left side Miter right at 45° Save right side of cut Miter left at 45° Save right side of cut Right side Miter left at 45° Save left side of cut Miter right at 45° Save left side of cut Special Cuts NEVER MAKE ANY CUT UNLESS THE MATERIAL IS SECURED ON THE TABLE AND AGAINST THE FENCE. ALUMINUM CUTTING (FIG. 28, 29) ALWAYS USE THE APPROPRIATE SAW BLADE MADE ESPECIALLY FOR CUTTING ALUMINUM. These are available at your local DeWALT retailer or DeWALT service center. Certain workpieces, due to their size, shape or surface finish, may require the use of a clamp or fixture to prevent movement during the cut. Position the material so that you will be cutting the thinnest cross section, as shown in Figure 28. Figure 29 illustrates the wrong way to cut these extrusions. Use a stick wax cutting lubricant when cutting aluminum. Apply the stick wax cutting lubricant directly to the saw blade before cutting. Never apply stick wax to a moving blade. The wax, available at most hardware stores and industrial mill supply houses, provides proper lubrication and keeps chips from adhering to the blade. Be sure to properly secure workpiece. Refer to Saw Blades under Optional Accessories for correct saw blade. FIG. 28 FIG. 29 BLADE BLADE FENCE FENCE CORRECT INCORRECT BOWED MATERIAL (FIG. 30, 31) When cutting bowed material always position it as shown in Figure 30 and never like that shown in Figure 31. Positioning the material incorrectly will cause it to pinch the blade near the completion of the cut. FIG. 30 FIG. 31 CORRECT INCORRECT CUTTING PLASTIC PIPE OR OTHER ROUND MATERIAL Plastic pipe can be easily cut with your saw. It should be cut just like wood and CLAMPED OR HELD FIRMLY TO THE FENCE TO KEEP IT FROM ROLLING. This is extremely important when making angle cuts. 17