HP LaserJet 1005 HP LaserJet 1005 series printer - User Guide - Page 78

Labels, Transparencies, Envelopes, Envelope construction, Envelopes with double-side seams

|

View all HP LaserJet 1005 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 78 highlights

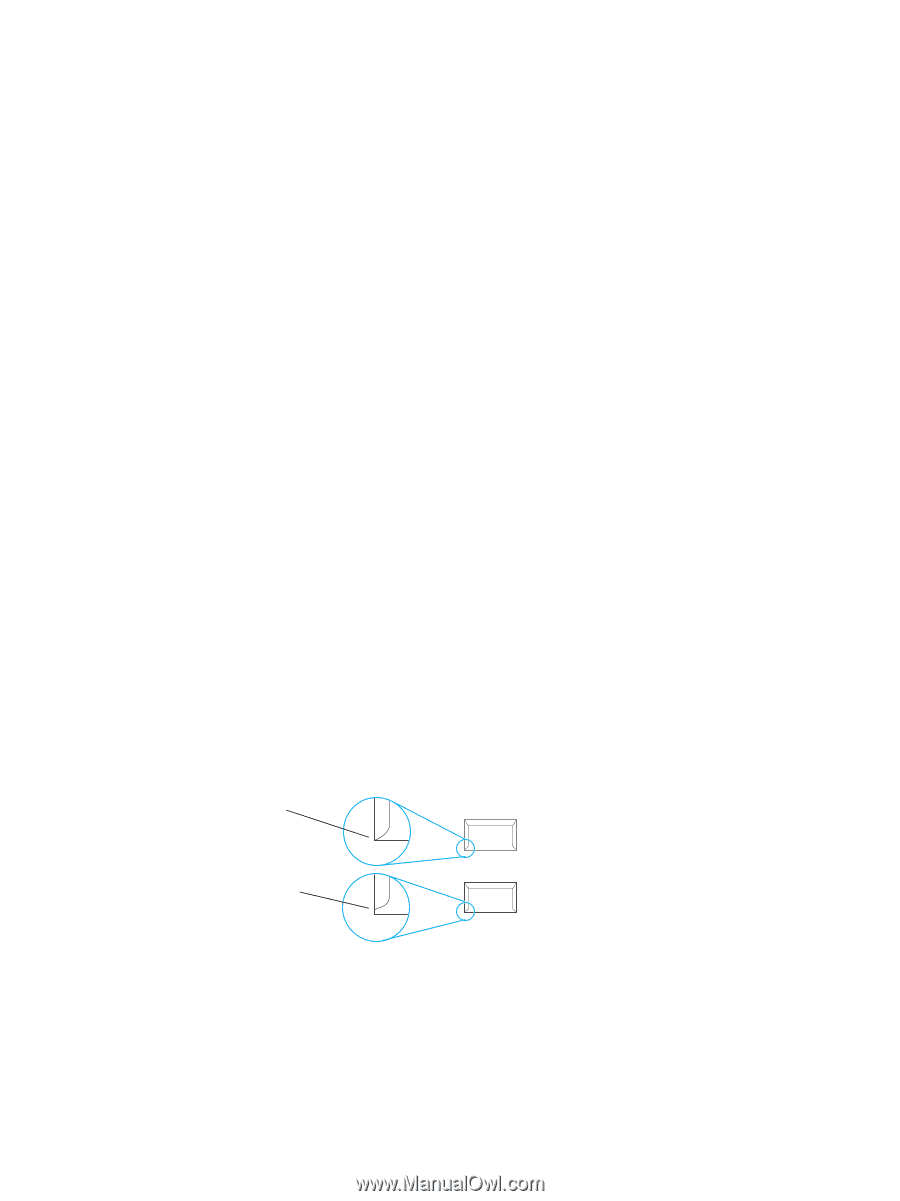

Labels When selecting labels, consider the quality of the following components: ● Adhesives: The adhesive material should be stable at 200° C (392° F), the printer's maximum temperature. ● Arrangement: Only use labels that do not have exposed backing between them. Labels can peel off of sheets that have spaces between the labels, causing serious jams. ● Curl: Prior to printing, labels must lie flat with no more than 13 mm (0.5 in.) of curl in any direction. ● Condition: Do not use labels with wrinkles, bubbles, or other indications of separation. Transparencies Transparencies must be able to withstand 200° C (392° F), the printer's maximum temperature. Envelopes Envelope construction Envelope construction is critical. Envelope fold lines can vary considerably, not only between manufacturers, but also within a box from the same manufacturer. Successful printing on envelopes depends on the quality of the envelopes. When selecting envelopes, consider the following components: ● Weight: The weight of the envelope paper should not exceed 28 lb (105 g/m2), or jamming might result. ● Construction: Prior to printing, envelopes should lie flat with less than 6 mm (0.25 in.) curl and should not contain air. Envelopes that trap air may cause problems. ● Condition: Make sure that the envelopes are not wrinkled, nicked, or otherwise damaged. ● Sizes: From 90 x 160 mm (3.5 x 6.3 in.) to 178 x 254 mm (7 x 10 in.). Envelopes with double-side seams An envelope with double-side-seam construction has vertical seams at both ends of the envelope rather than diagonal seams. This style might be more likely to wrinkle. Make sure that the seam extends all the way to the corner of the envelope as shown in the following illustration: Acceptable Unacceptable 76 Appendix B Media specifications ENWW