Lexmark 4076 Execjet II Service Manual - Page 24

Maintenance Station Service Check, Seals the print head when it is not being used to prevent the noz

|

View all Lexmark 4076 Execjet II manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 24 highlights

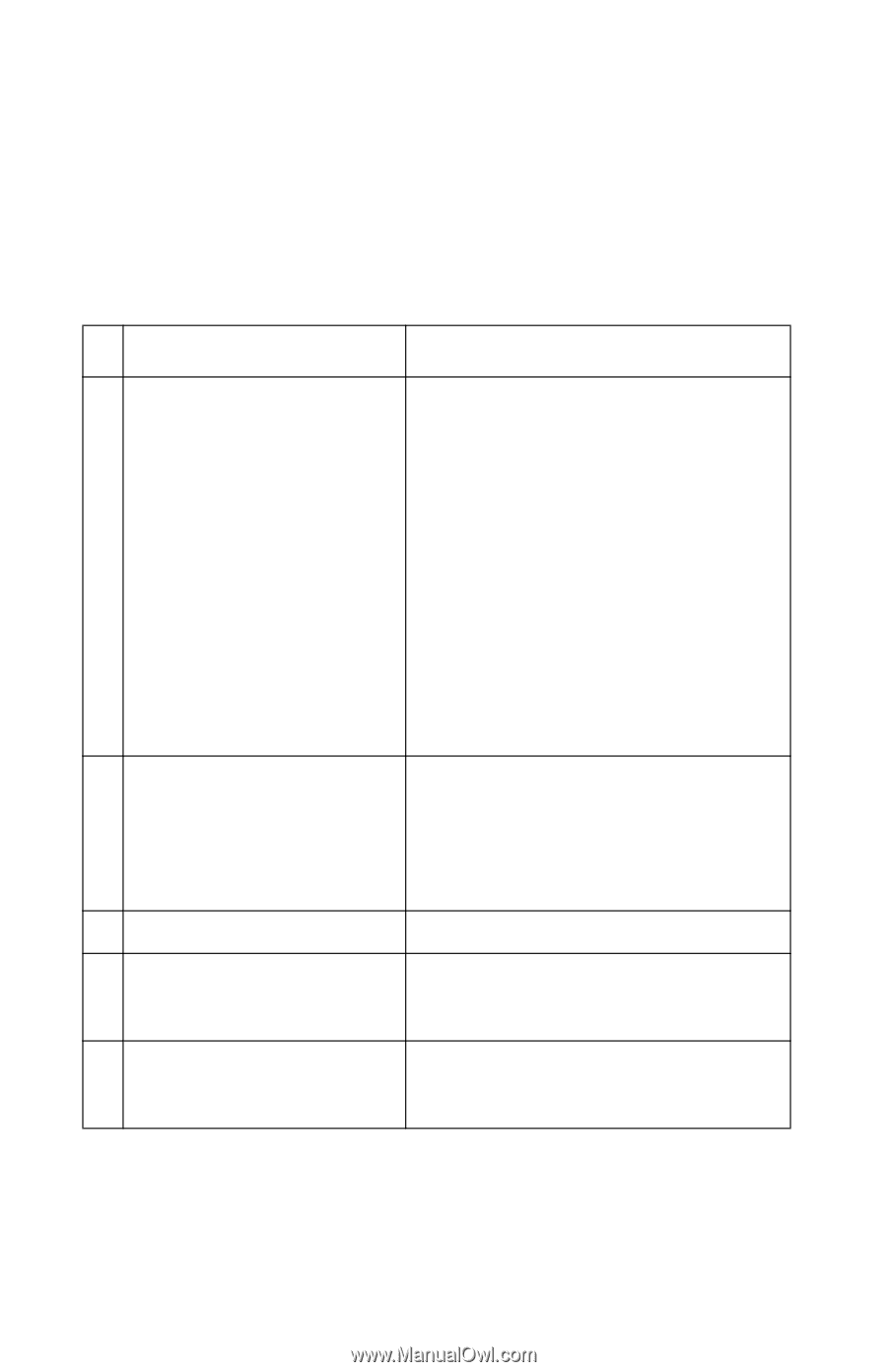

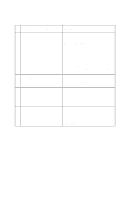

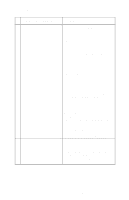

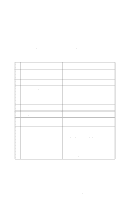

4076-0XX Maintenance Station Service Check The maintenance station has two functions: 1. Cleans the print head nozzles during the print operation. 2. Seals the print head when it is not being used to prevent the nozzles from drying.. FRU OR PROCEDURE 1 Maintenance Drive Assem- bly 2 System Board 3 Maintenance Rocker Am. 4 Wiper 5 Cap ACTION Disconnect J4 from the system board. Check for 18 ohms (±4 ohms) between pins 1 and 2 at the motor. If the reading is incorrect, replace the maintenance drive assembly, Check for motor pins shorted to the motor housing. If you find a shorted pin, replace the maintenance drive assembly. If the symptom remains, replace the system board. A bind in the drive assembly can prevent the motor from turning. Check for binds and loose or worn parts in the drive assembly. Also check the motor gear Turn the printer off and disconnect J4 from the system board. Turn the printer on and check for a pulse of 15 V dc between J4-1 and ground on the system board as the printer goes through POST. Check for binds or wear. A worn wiper will cause degraded print quality just after a maintenance cleaning. Check for loose or worn wiper. A worn cap will cause the print head nozzles to dry and clog. Check for loose or worn cap. Note: if the failure remains, replace the system board 12