Ricoh Pro C900 User Guide - Page 90

Other Adjustment Settings, Air Feed Start Time Adj.

|

View all Ricoh Pro C900 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 90 highlights

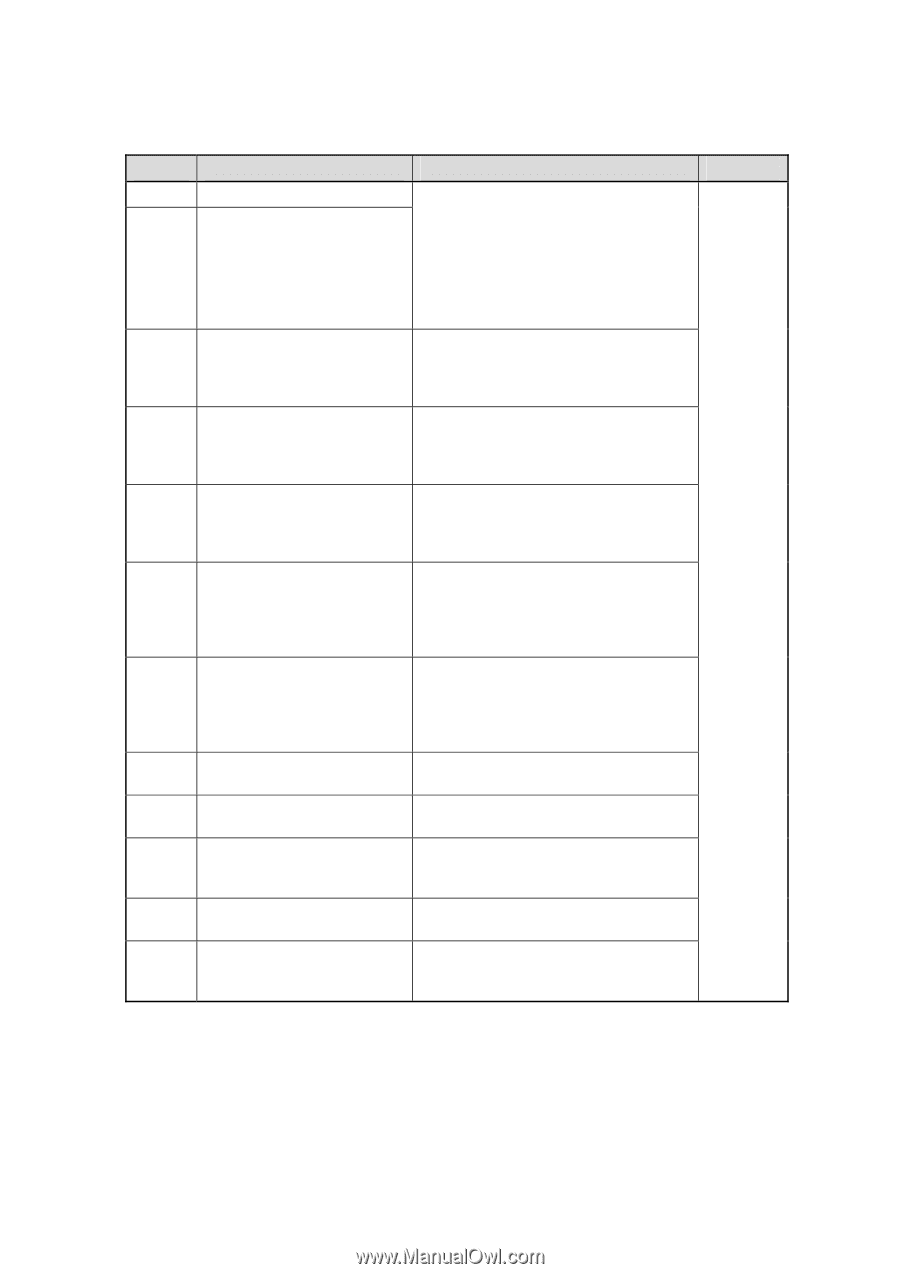

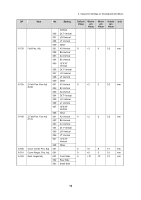

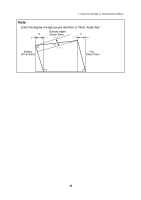

u Other Adjustment Settings SP Item 1-730 Detect Skew 1-761 Detect Side Regist 1-906 Paper Curl Adjustment 1-908 Erase Paper Lead Edge 1-910 Detect Multi Feed 1-920 Blow Fan Duty Adj. 1-921 Air Feed Start Time Adj. 2-810 Clear blurred img 3-309 Oil removal mode 3-801 Initialize T Sensor 3-820 Execute Density Adj. 6-770 Stacker Full Setting 3. Values for Settings on the [Adjustment] Menu Description Reference Use this if the print image is misaligned by more than 2-3 mm when printing on color, pre-printed, or narrow sheets up to 147 mm wide. After disabling "Skew detection" and "Side-to-Side Registration" use the "Side-to-Side Registration1/2" setting to adjust the alignment. 3.2.4 Specify the method for straightening curled sheets. Select the method according to the direction and degree of curl. If paper frequently becomes jammed inside the fusing unit, adjust the paper edge margin settings. Specify this setting for each paper type. If double feeding is erroneously detected when delivering color, preprinted, or other special sheets, disable double-feed detection. If double feeding or paper jamming occurs when using the LCT, adjust the strength of the sheet separation airstream. Specify this setting for each LCT paper tray. If double-feeds or paper jams occurs when using the LCT, adjust the duration of the sheet separation airstream. Specify this setting for each LCT paper tray. Use this to remove dirt from the surface of the drum unit. Use this to remove oil from the surface of the drum unit and image transfer belt. The machine automatically performs the initialization process every time the developer is replaced. The machine automatically performs the print density adjustment process. Specify the height limit of the delivered paper stack. Select 100%, 75%, 50%, or 25%. 10