Ridgid R4030 Operation Manual - Page 21

To Make A Bevel Cut, To Make A Plunge Cut

|

View all Ridgid R4030 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 21 highlights

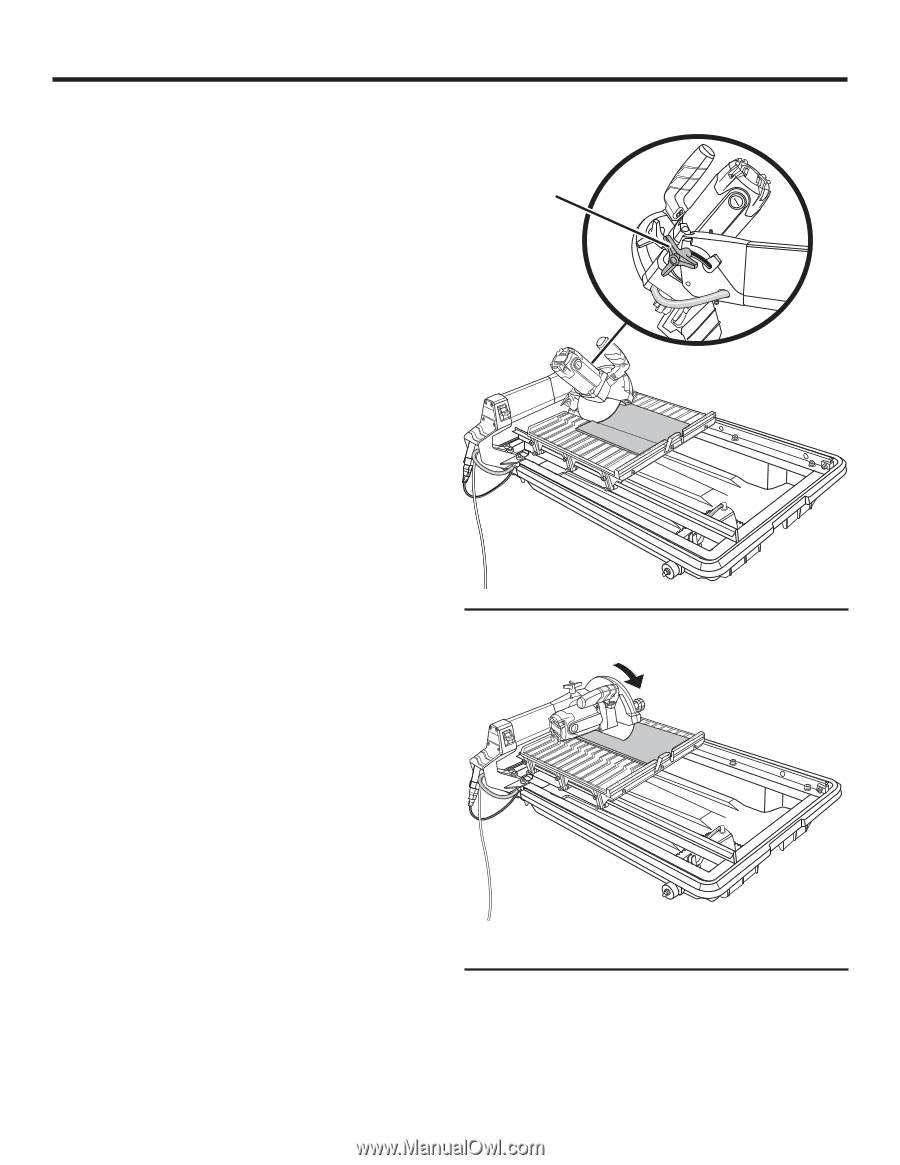

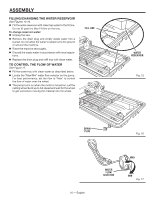

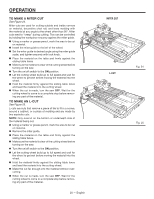

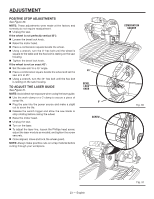

OPERATION Turn the material over and make the second cut along one of the marks. This time overcut the other line and the cut piece should separate from the rest of the material. When the second cut is made, turn the saw OFF. Wait for the cutting wheel to come to a complete stop before removing any part of the material. TO MAKE A BEVEL CUT See Figure 26. Bevel 45° cuts can be made using this saw. Using a marker or grease pencil, mark the area to be cut on material. Slide the saw table to the front of the water tray before tilting the saw head. Loosen the bevel knob and tilt the motor head. Turn the on/off switch to the ON position. Let the cutting wheel build up to full speed and wait for the wheel to get wet before moving the material into the wheel. Hold the material firmly against the sliding table fence and feed the material into the cutting wheel. When the cut is made, turn the saw OFF. Wait for the cutting wheel to come to a complete stop before removing any part of the material. TO MAKE A PLUNGE CUT See Figure 27. Plunge cuts are made by positioning the material directly underneath the cutting wheel and lowering the wheel onto the workpiece. This allows pieces to be cut from the center of the material. Using a marker or grease pencil, mark the area to be cut on material. Loosen the lock knob on the motor head and position the motor head upward to its maximum height. Turn the on/off switch to the ON position. Let the cutting wheel build up to full speed and wait for the wheel to get wet before moving the material into the wheel. Hold the motor head firmly by the handle. Move the material into the desired position for cutting. Slowly lower the motor head into the material to make the cut. Raise the motor head. Turn the on/off switch to the OFF position. Slide the table away from the motor head then position the work material for the next cut. BEVEL KNOB BEVEL CUT 45 PLUNGE CUT 0 Fig. 26 Fig. 27 21 - English