Ridgid R4030 Operation Manual - Page 25

Brush Replacement, Cleaning The Water Nozzle

|

View all Ridgid R4030 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 25 highlights

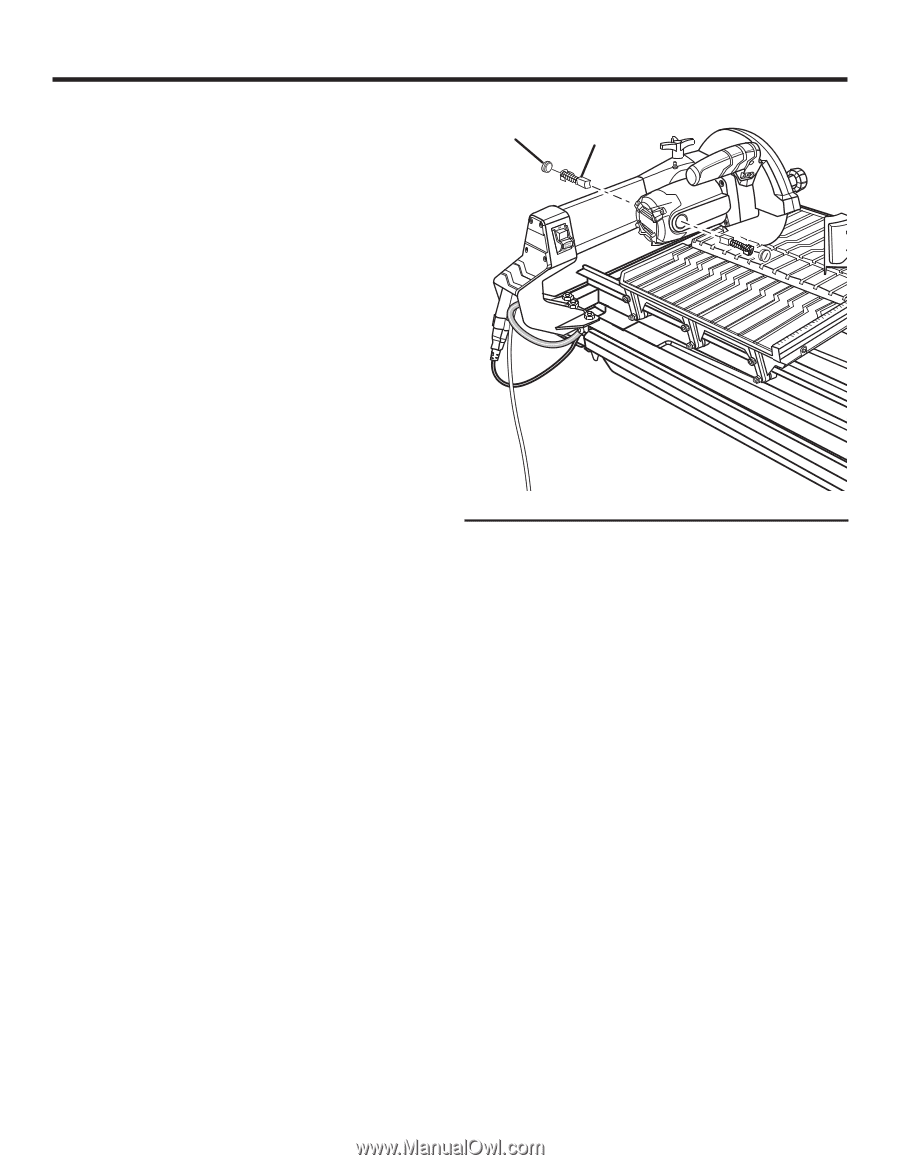

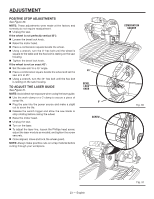

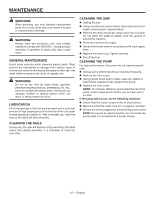

MAINTENANCE BRUSH REPLACEMENT See Figure 32. The saw has externally accessible brush assemblies that should be periodically checked for wear. Proceed as follows when replacement is required: Unplug the saw. Remove brush cap with a screwdriver. Brush assembly is spring loaded and will pop out when you remove brush cap. Remove brush assembly. Check for wear. Replace both brushes when either has less than 1/4 in. length of carbon remaining. Do not replace one side without replacing the other. Reassemble using new brush assemblies. Make sure curvature of brush matches curvature of motor and that brush moves freely in brush tube. Make sure brush cap is oriented correctly (straight) and replace. Tighten brush cap securely. Do not overtighten. CLEANING THE WATER NOZZLE If the water nozzles become clogged with debris, they shouild be removed and rinsed with clean water. The nozzles just push on and pull off the connector on either side of the cutting wheel. BRUSH CAP BRUSH ASSEMBLY Fig. 32 25 - English