Stihl FS 360 C-EM Instruction Manual - Page 45

Inspections and Maintenance, by Dealer

|

View all Stihl FS 360 C-EM manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 45 highlights

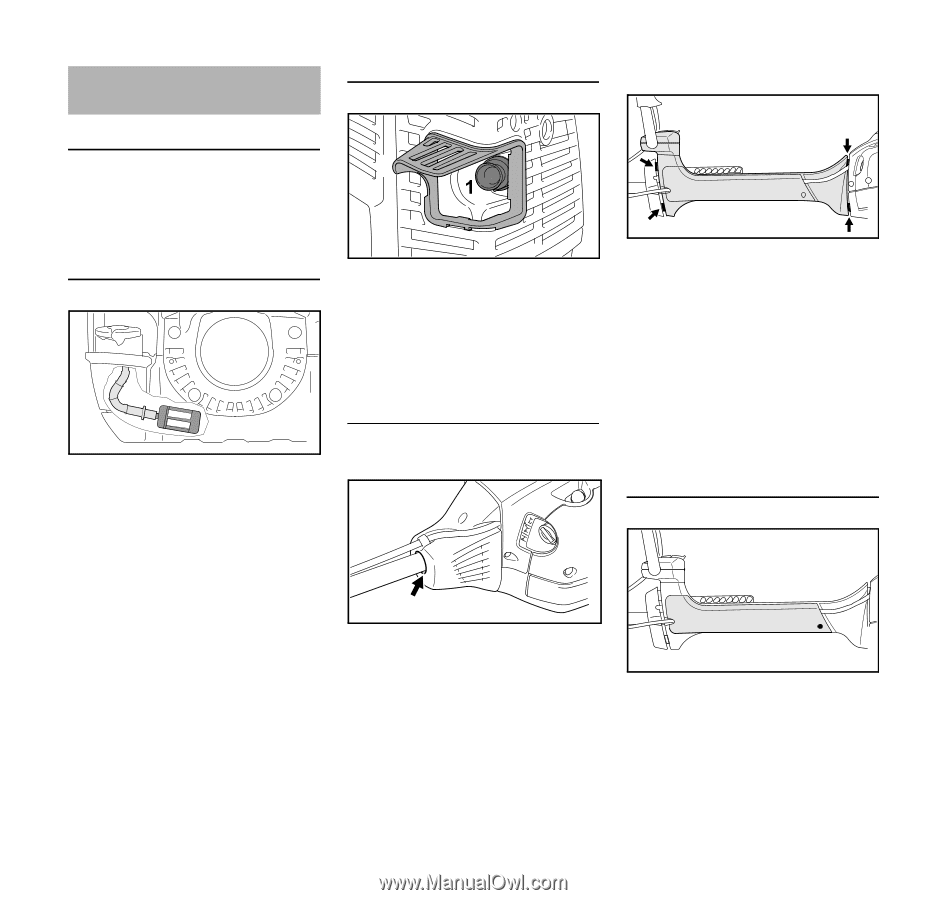

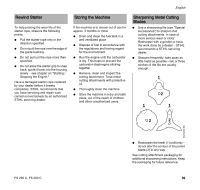

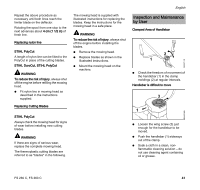

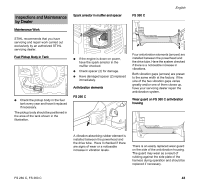

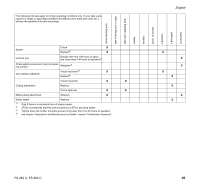

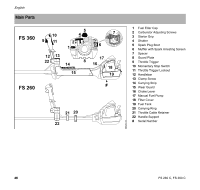

6BA015 KN Inspections and Maintenance by Dealer Maintenance Work STIHL recommends that you have servicing and repair work carried out exclusively by an authorized STIHL servicing dealer. Fuel Pickup Body in Tank N Check the pickup body in the fuel tank every year and have it replaced if necessary. The pickup body should be positioned in the area of the tank shown in the illustration. 9926BA031 KN Spark arrestor in muffler and spacer 2 N If the engine is down on power, have the spark arrestor in the muffler checked. N Check spacer (2) for damage. N Have damaged spacer (2) replaced immediately. Antivibration elements FS 260 C 3BA035 KN FS 360 C English Four antivibration elements (arrows) are installed between the powerhead and the drive tube. Have the system checked if there is a noticeable increase in vibrations. Both vibration gaps (arrows) are preset to the same width at the factory. If the size of the two vibration gaps varies greatly and/or one of them closes up, have your servicing dealer repair the antivibration system. Wear guard on FS 360 C antivibration housing 9926BA033 KN 6BA026 KN FS 260 C, FS 360 C A vibration-absorbing rubber element is installed between the powerhead and the drive tube. Have it checked if there are signs of wear or a noticeable increase in vibration levels. There is an easily replaced wear guard on the side of the antivibration housing. The guard may wear as a result of rubbing against the side plate of the harness durng operation and should be replaced if necessary. 43