Lexmark MX310 Card Stock & Label Guide - Page 142

Paper source, Labels, Paper, web paper, Polyester, Vinyl, print within 1 mm 0.040 inch of the die-cut.

|

View all Lexmark MX310 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 142 highlights

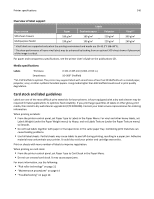

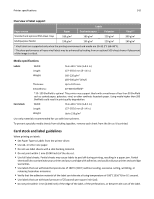

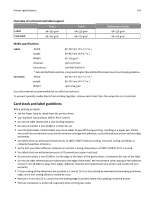

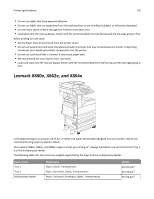

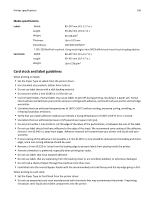

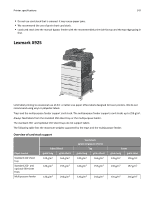

Printer specifications 142 Overview of label support Labels Paper source Paper Dual‑web paper Polyester Vinyl1, 2 Standard and optional 550‑sheet trays 180 g/m2 180 g/m2 220 g/m2 300 g/m2 Multipurpose feeder 199 g/m2 199 g/m2 220 g/m2 260 g/m2 1 Vinyl labels are supported only when the printing environment and media are 20-32.2°C (68-90°F). 2 The skew performance of heavy vinyl labels may be enhanced by feeding from an optional 500‑sheet drawer if placement of the image is critical. Media specifications Labels Card stock Width: 76.2-139.7 mm (3-8.5 in.) Length: 127-355.6 mm (5-14 in.) Weight: 160-220 g/m2 160-300 g/m2 (Vinyl) Thickness: Up to 0.25 mm Smoothness: 50-300 Sheffield* * 50-150 Sheffield is optimal. This printer may support labels with smoothness of less than 50 Sheffield such as coated paper, polyester, vinyl, or other synthetic facestock paper. Using media higher than 200 Sheffield could result in print quality degradation. Width: 76.2-139.7 mm (3-8.5 in.) Length: 127-355.6 mm (5-14 in.) Weight: Up to 216 g/m2 Use only materials recommended for use with laser printers. To prevent specialty media sheets from sticking together, remove each sheet from the bin as it is printed. Card stock and label guidelines When printing on labels: • Set Paper Type to Labels from the printer driver. • Use A4- or letter-size paper. • Do not use label sheets with a slick backing material. • Do not print within 1 mm (0.040 inch) of the die-cut. • Use full label sheets. Partial sheets may cause labels to peel off during printing, resulting in a paper jam. Partial sheets will also contaminate your printer and your cartridge with adhesive, and could void your printer and cartridge warranties. • Use labels that can withstand temperatures of 180°C (356°F) without sealing, excessive curling, wrinkling, or releasing hazardous emissions. • Verify that the adhesive material of the label can tolerate a fusing temperature of 180°C (356°F) for 0.1 second. • Use labels that can withstand pressure of 25 pounds per square inch (psi). • Do not print within 1 mm (0.040 inch) of the edge of the label, of the perforations, or between die-cuts of the label.