Lexmark MX310 Card Stock & Label Guide - Page 160

Optra Es special media printer, Selecting and loading media

|

View all Lexmark MX310 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 160 highlights

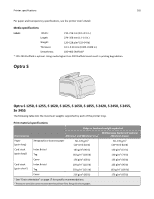

Printer specifications 160 Optra Es special media printer The Optra Es printer has highly precise print registration and excellent feeding reliability. It was designed to handle a wide range of paper and card stock weights, as well as continuous printing of labels. The following table lists the maximum weights supported by Tray 1 and the manual feed slot. Overview of card stock and label support Paper source Tray 1 Manual feed slot Index Bristol 199 g/m2 199 g/m2 Card stock Tag 163 g/m2 163 g/m2 Cover 176 g/m2 176 g/m2 For paper and transparency specifications, see the printer User's Guide. Labels Paper Vinyl 180 g/m2 300 g/m2 180 g/m2 300 g/m2 Selecting and loading media Your printer can accept a wide range of paper or card stock weights, but materials either too light or too heavy can cause paper handling and print quality problems. Heavier weight materials can cause fusing problems because of the mass of material the fuser must heat quickly. Heavy materials may also feed less reliably or skew because of their weight or stiffness. Lighter materials can wrinkle or jam. When you use preprinted forms, make sure the ink on the forms can withstand the printer fuser temperature of 200°C (392°F); otherwise, you risk contaminating the printer or creating hazardous fumes. When you select the correct Paper Type (Normal, Rough Paper, Card Stock, Transparency, Labels) from MarkVision Professional, your printer automatically optimizes print quality and toner adhesion. Feed labels, card stock, transparencies, and envelopes from Tray 1 or the manual feed slot. Reserve Tray 2 for 20-24 lb bond paper. Do not load labels together with other media in the same paper tray; combining different print media can cause feeding problems. To avoid curl, do not leave labels in the tray overnight. When feeding labels from Tray 1, push the label lever to the left. When printing on other media, push the lever to the right. To improve feed reliability, flex the print media before placing it in the paper tray.