Lexmark MX310 Card Stock & Label Guide - Page 26

Stripped edge matrix guidelines, T610, and T630 laser printers.

|

View all Lexmark MX310 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 26 highlights

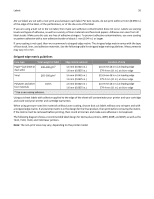

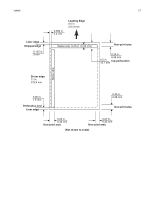

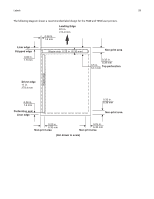

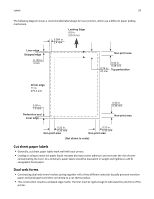

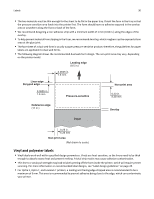

Labels 26 Die‑cut labels are cut with a non‑print area between each label. For best results, do not print within 2.3 mm (0.090 in.) of the edge of the label, of the perforations, or of the die‑cuts of the label. If you are using a butt cut or die‑cut label, then make sure adhesive contamination does not occur. Labels use varying levels and types of adhesive, as well as a variety of liner materials and facestock papers. Adhesive can ooze from all label stocks. Make sure die‑cuts are free of adhesive stringers. To prevent adhesive contaminations, use zone coating or pattern adhesive with a non‑adhesive border of about 1‑mm (0.04‑in.) or larger. If zone coating is not used, then we recommend a stripped edge matrix. The stripped edge matrix varies with the type of face stock, liner, and adhesive materials. See the following table for stripped edge matrix guidelines. Measurements may vary ±0.5 mm. Stripped edge matrix guidelines Face type Total weight of label Paper* (cut sheet or dual web) 140-180 g/m2 Vinyl 265-300 g/m2 Polyester and other face materials Varies * Use a non‑oozing adhesive. Edge matrix removal 1.6 mm (0.0625 in.) 1.6 mm (0.0625 in.) 1.6 mm (0.0625 in.) 1.6 mm (0.0625 in.) 1.6 mm (0.0625 in.) 1.6 mm (0.0625 in.) Location of strip 215.9 mm (8.5 in.) at leading edge 279.4 mm (11 in.) at driver edge 215.9 mm (8.5 in.) at leading edge 279.4 mm (11 in.) at driver edge 215.9 mm (8.5 in.) at leading edge 279.4 mm (11 in.) at driver edge Using cut sheet labels with adhesive applied to the edge of the sheet will contaminate your printer and your cartridge and could void your printer and cartridge warranties. When using pressure‑sensitive materials without zone coating, choose butt cut labels without any stringers and with a stripped edge matrix. If a total strip matrix is in the design for the final product, then print before removing the matrix. If the matrix must be removed before printing, then round all corners and make sure adhesive is not exposed. The following diagram shows a recommended label design for Optra plus printers, 4039, 4029, and 4019, as well as the T610, T520, T620, and T630 laser printers. Note: The non‑print area may vary, depending on the printer model.