Lexmark MX310 Card Stock & Label Guide - Page 143

Lexmark X850, X852e, and X854e, We recommend the use of grain short card stock.

|

View all Lexmark MX310 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 143 highlights

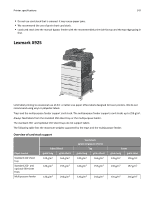

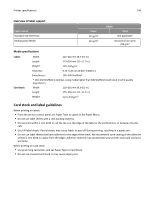

Printer specifications 143 • Do not use label sheets that have adhesive to the edge of the sheet. We recommend zone coating of the adhesive at least 1 mm (0.040 inch) away from edges. Adhesive material will contaminate your printer and could void your warranty. • If zone coating of the adhesive is not possible, a 3‑mm (0.125‑inch) strip should be removed on the leading and driver edge, and a non‑oozing adhesive should be used. • Remove a 3‑mm (0.125‑inch) strip from the leading edge to prevent labels from peeling inside the printer. • Portrait orientation is preferred, especially when printing bar codes. • Do not use labels that have exposed adhesive. • Do not use labels that are separating from the backing sheet or are wrinkled, bubbled, or otherwise damaged. • Do not load a sheet of labels through the machine more than once. • Load labels into the multipurpose feeder with the recommended print side faceup and the top edge entering the printer first. When printing on card stock: • Set Paper Type to Card Stock from the printer driver. • Do not use preprinted card stock manufactured with chemicals that may contaminate the printer. Preprinting introduces semi‑liquid and volatile components into the printer. • Do not use creased card stock. It may cause paper jams. • We recommend the use of grain short card stock. • Load card stock into the multipurpose feeder with the recommended print side faceup and the top edge entering the printer first. Lexmark X850, X852e, and X854e Limit label printing to occasional use of paper office labels designed for laser printers. Paper labels are supported in Tray 1, Tray 2, and the manual bypass feeder. The following table lists the maximum weights supported. Note: Scanning large quantities of labels is not recommended.