Lexmark MX310 Card Stock & Label Guide - Page 48

Lexmark C752

|

View all Lexmark MX310 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 48 highlights

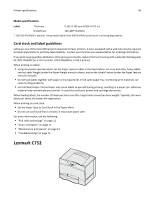

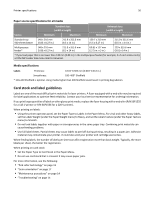

Printer specifications 48 Media specifications Labels Thickness: 0.102-0.305 mm (0.004-0.012 in.) Smoothness: 100-400* Sheffield * 150-250 Sheffield is optimal. Using media higher than 300 Sheffield could result in printing degradation. Card stock and label guidelines Labels are one of the most difficult print materials for laser printers. A fuser equipped with a web oiler may be required for label applications to optimize feed reliability. Contact your local service representative for ordering information. If you print large quantities of labels or other glossy print media, replace the fuser housing with a web oiler field upgrade kit (P/N 12G6307 for a 115 V printer, P/N 12G6308 for a 220 V printer). When printing on labels: • Using the printer operator panel, set the Paper Type to Labels in the Paper Menu. For vinyl and other heavy labels, set the Labels Weight (under the Paper Weight menu) to Heavy, and set the Labels Texture (under the Paper Texture menu) to Smooth. • Do not load labels together with paper or transparencies in the same paper tray. Combining print materials can cause feeding problems. • Use full label sheets. Partial sheets may cause labels to peel off during printing, resulting in a paper jam. Adhesive material may contaminate your printer. It could also void your printer and cartridge warranties. When feeding labels, the number of labels per sheet can affect registration more than basis weight. Typically, the more labels per sheet, the better the registration. When printing on card stock: • Set the Paper Type to Card Stock in the Paper Menu. • Do not use card stock that is creased. It may cause paper jams. For more information, see the following: • "Pick roller technology" on page 11 • "Grain orientation" on page 17 • "Maintenance procedures" on page 14 • "Troubleshooting" on page 14 Lexmark C752