Lexmark MX310 Card Stock & Label Guide - Page 21

aligned with the ribs in the duplex or redrive areas of the printer. This eliminates

|

View all Lexmark MX310 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 21 highlights

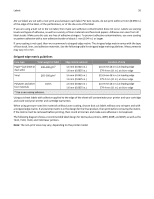

Labels 21 When developing a paper label for duplexing, the converter should make sure that the label is designed to protect against contamination or buildup. Contamination could result in paper feed problems and paper jams. We recommend the use of label sheets that have a non-adhesive border around the label area. Make sure that the release strength is enough to withstand temperatures of 225°C (437°F) and pressure up to 25 psi. The ability to withstand these factors is important because the label sheet will be subjected to these twice. Use label ties whenever possible. These small uncut areas (approximately 1.6 mm or 0.06 in.) help stabilize the label sheet and prevent tearing at perforations and die-cuts during printing. Label ties also prevent labels from predispensing in the printer. The slits and cuts in the labels expose the adhesives to the printer. For best results when duplexing labels, position the label sheet so the slits and cuts are not aligned with the ribs in the duplex or redrive areas of the printer. This eliminates any contact points between the label adhesive and the printer, thereby preventing any adhesive contamination in the printer. The following graphics show the rib locations for the Optra S, Optra T, and Lexmark T, respectively. Optra S rib locations (rib width = 2 mm): 20 mm 21 mm 27 mm 22 mm 15.5 mm 21.5 mm 28 mm 26 mm 17 mm 15 mm Reference Plate Optra T and Lexmark T rib locations (rib width = 2 mm): 16 mm 11 mm 15 mm 13 mm 16 mm 17 mm 26 mm 18 mm 12 mm 20 mm 15 mm 12 mm 4.02 mm Reference Plate