Lexmark MX310 Card Stock & Label Guide - Page 22

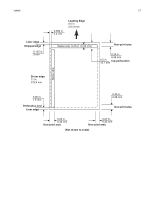

Primary rib pattern design guidelines for reference edge alignment - parts

|

View all Lexmark MX310 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

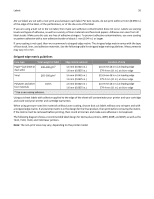

Labels 22 Load label sheets with the label end first. Use grain long paper instead of grain short paper, which tends to curl easily. If a converter develops a grain short label sheet for duplexing, then test the sheet first to make sure it works satisfactorily. Note: We recommend testing any material with your application and printer before purchasing large quantities. To use the duplex label application, you must install a special fuser wiper. Printer Fuser wiper part number S1855, T612, T614, T520, and T522 99A1082 T620 and T622 18A1467 T630, T632 and T634 56P2109 T64x, X644e, and X646e 40X2666 T65x and X65x 40X2666 The wiper makes it possible to print on both sides of paper labels specifically designed for duplexing. You may also use the wiper when using the printer to print on one side of a label sheet or both sides of a sheet of paper. When ordering a new cartridge, be sure to order the cartridge that includes the correct fuser wiper. Primary rib pattern design guidelines for reference edge alignment The function of the primary rib pattern is to provide the best support to the media during transport. If it is known that the media will be touching a certain surface, then that surface must contain the primary rib pattern. The feed path should guide the leading edge of the media into the primary guide surface and not the secondary surface. This provides a determinate location for the leading edge of the media on the guide surface that provides the best support. The incidence angle of the leading edge of the media as it touches the primary guide surface should be no more than 30°. This eliminates media stubbing on the guides and reduces the amount of energy input into the media by the guide. The primary rib pattern is to have the rib support extending out to between 3 to 10 mm from the edge of the paper and 2 to 10 mm from the edge of the envelopes. This keeps the corners of the media stiff so that it cannot fold and catch other surfaces in the printer. It also prevents the corners of the media from catching the inside surface of a paper path rib. The primary rib pattern should not have any ribs closer than 3 mm to the outside edge of paper and envelopes. This keeps the media from stubbing into a rib that is too close to the edge of the media. The maximum rib spacing of the primary rib pattern should not be greater than 20 mm. This keeps the leading edge of the media flat as it moves through the system.