Lexmark MX310 Card Stock & Label Guide - Page 24

Adhesives, C770, C792e, C935, CS310n - test print page

|

View all Lexmark MX310 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 24 highlights

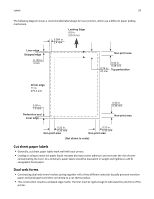

Labels 24 Printers using a corner buckler Printers using an auto compensator • 4019, 4029, 4039, 4049 • Lexmark E220, E320, E321, E322, E323, T420, W820, X422 • Optra 12L, 12R, Lxi, Lx, Rx • Optra R+, Rt+, Lx+, Lxi+ • Optra C, Optra Color 1200, Optra N • Optra M410, M412, W810 • C910, C912, C920 • Lexmark E230, E232, E234(n), E330, E332n, E260, E360, E460, C510, C520, C522, C524, C530, C532, C534, C540, C734, C736, C750, C752, C760, C762, C770, C772, C780, C782, C792e, C792de, C792dte, C792dhe, C935, CS310n, CS310dn, CS410n, CS410dn, CS510de, CX310n, CX310dn, CX410e, CX410de, CX410dte, CX510de, CX510dhe, CX510dthe, T520, T522, T620, T622, T630, T632, T634, T640, T642, T644, T650, T652, T654, T656dne, X203, X204, X215, X264, X363, X364, X463, X464, X466, X540, X642e, X644e, X646e, X651, X652, X654, X656, X658, X734, X736, X738, X792de, X792dte, X792dtfe, X792dtpe, X792dtme, X792dtse, W840 • Optra S 1250, S 1650, S 2450 • Optra S 1255, S 1625, S 1855, S 2455 • Optra Se 3455 • Optra T610(n), T612(n), T614(n), T616(n) Some liner materials used in pressure‑sensitive constructions are called label papers. Label papers are either machine finish (MF) or English finish (EF) papers that are calendered, supercalendered, or coated on one side. An MF has varying degrees of surface smoothness. The smoothness is determined by the number of times the paper passes through the rollers (wet or dry) during manufacturing. An EF is uncoated and low gloss in appearance. Label papers may also be used as the face sheet for pressure‑sensitive paper products, such as the materials used in dual web forms construction. Supercalendering produces high gloss surfaces that may be slick. Some supercalendered liners are difficult for printers to pick and feed reliably. We do not recommend using supercalendered liners designed for high‑speed laser printers (50 or more pages per minute). Some pressure‑sensitive constructions use Kraft liners or bleached Kraft liners. Kraft liners are made from sulfate pulp and are MF or machine glazed (MG). Most MG papers have a high gloss appearance. High gloss, glazed surfaces may increase skew and are more difficult for the printer feed mechanism to handle reliably. Some Kraft liners may produce acceptable results; however, we strongly recommend extensive testing of pressure‑sensitive constructions using Kraft liners. Tissue‑backed or plain bond liners reduce toner contamination inside the printer and improve feed performance. Slick, non‑porous liners are harder to feed and increase toner buildup in the fuser and on the backup roll. Rough backings, on the other hand, can increase paper path friction, which can cause skew and paper jams. The face material of the liner needs to have a melt temperature that can also withstand the fuser temperatures of nearly 225°C (437°F). Since there is a stripped area of a maximum of 3 mm, this can expose the face material to these temperatures and could cause melting or contamination in the fuser. Excessive paper dust or chaff associated with the liner may affect print quality. If a liner material produces excessive paper dust or chaff during the conversion process, some of this debris may be packaged with the material and end up in the printer. Liner materials that produce excessive paper dust or chaff as they feed through the printer may also affect print quality. Your forms supplier can provide additional information on liners. Adhesives There are three basic types of label adhesives: removable, permanent, and semi‑permanent (cold temp). All types, with proper design, can be used with your printer. Acrylic‑based adhesives are generally preferred for cut‑sheet label printers.