Lexmark MX310 Card Stock & Label Guide - Page 164

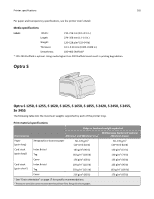

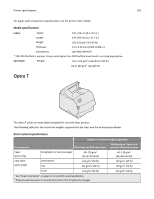

Optra N

|

View all Lexmark MX310 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 164 highlights

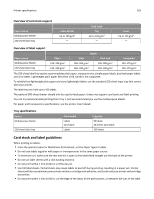

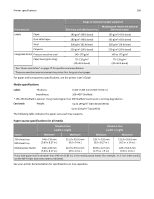

Printer specifications 164 • Do not use label sheets that have adhesive to the edge of the sheet. We recommend zone coating of the adhesive at least 1 mm (0.040 in.) away from edges. Adhesive material will contaminate your printer and could void your warranty. • If zone coating of the adhesive is not possible, a 3‑mm (0.125‑in.) strip should be removed on the leading and driver edge, and a non‑oozing adhesive should be used. • Remove a 3‑mm (0.125‑in.) strip from the leading edge to prevent labels from peeling inside the printer. • Portrait orientation is preferred, especially when printing bar codes. • Do not use labels that have exposed adhesive. • For best results when using the multipurpose feeder, dual web and integrated labels should be fed paper‑end first. • For best results when using the 250‑sheet label tray, dual web and integrated labels should be fed label‑end first. When printing on card stock: • From the operator panel or MarkVision Professional, set the Paper Type to Card Stock. • Do not use preprinted card stock manufactured with chemicals that may contaminate the printer. • Do not use card stock that is creased. It may cause paper jams. • To minimize curl, make sure the rear exit bin is open so the card stock feeds straight out the back of the printer. • We recommend the use of grain short card stock. For more information, see "Maintenance procedures" on page 14. Optra N Limit label printing to occasional use of paper office labels designed for laser printers. We do not recommend using vinyl or polyester labels. Always feed labels from the multipurpose tray. The multipurpose tray can hold up to 50 sheets of labels. The Optra N supports print materials up to 128 g/m2 (34 lb). The following table lists the maximum weights supported by the multipurpose tray. Overview of card stock and label support Paper source Multipurpose Tray Card stock Index Bristol Tag - - Cover - Labels Paper 128 g/m2 Vinyl -