Craftsman 22901 Instruction Manual - Page 4

General, Safety, Instructions, Before, Usung The, Df_ull Press - manual

|

View all Craftsman 22901 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 4 highlights

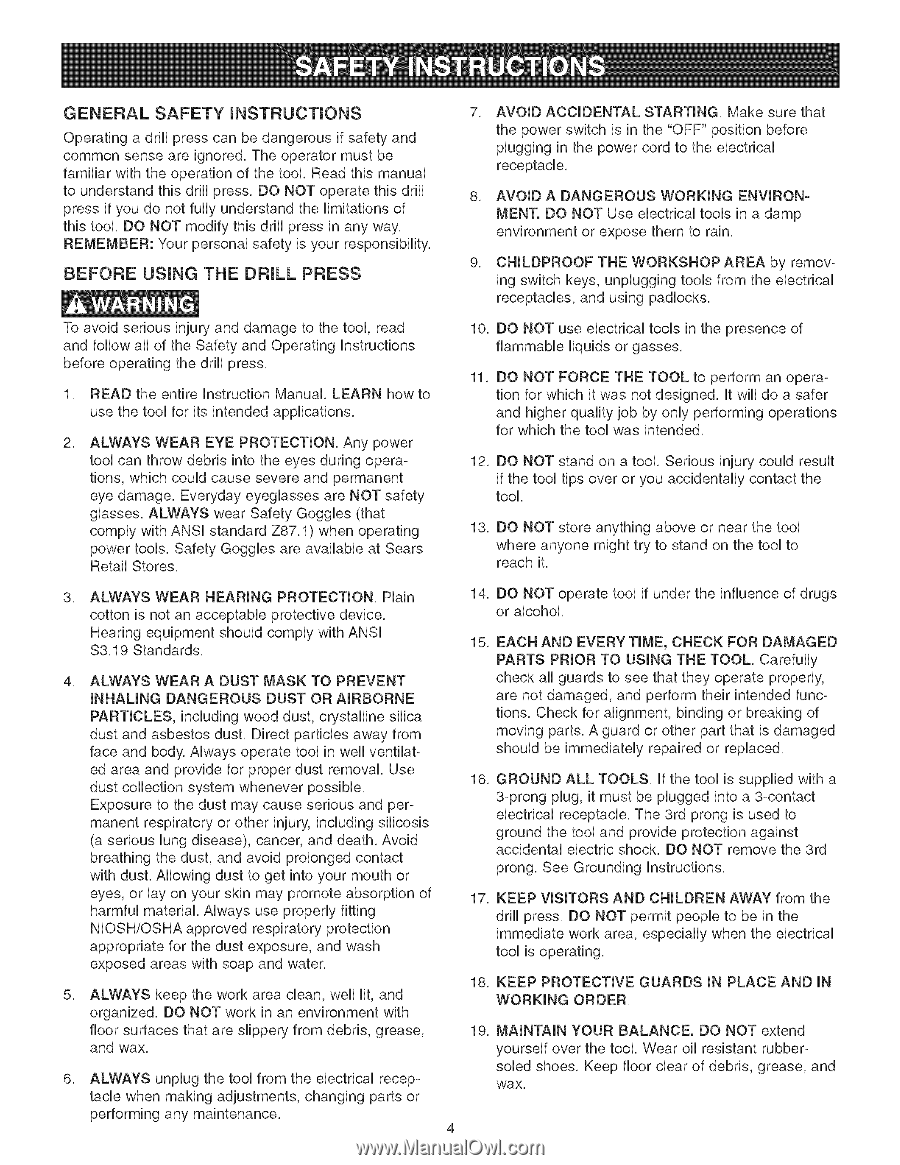

GENERAL SAFETY iNSTRUCTiONS Operating a drill press can be dangerous if safety and common sense are ignored, The operator must be familiar with the operation of the tool, Read this manual to understand this drill press, DO NOT operate this drill press if you do not fully understand the limitations of this tool, DO NOT modify this drill press in any way, REMEMBER: Your personal safety is your responsibility, BEFORE USUNG THE DF_ULL PRESS To avoid serious injury and damage to the tool, read and follow all of the Safety and Operating instructions before operating the drill press, 1, READ the entire instruction Manual, LEARN how to use the tool for its intended applications, 2, ALWAYS WEAR EYE PROTECTION, Any power tool can throw debris into the eyes during operations, which could cause severe and permanent eye damage, Everyday eyeglasses are NOT safety glasses, ALWAYS wear Safety Goggles (that comply with ANSi standard Z87,1) when operating power tools, Safety Goggles are available at Sears Retail Stores, 3, ALWAYS WEAR HEARING PROTECTION, Plain cotton is not an acceptable protective device, Hearing equipment should comply with ANSi $3,19 Standards, 4, ALWAYS WEAR A DUST MASK TO PREVENT INHALING DANGEROUS DUST OR AIRBORNE PARTICLES, including wood dust, crystalline silica dust and asbestos dust, Direct particles away from face and body, Always operate tool in well ventilated area and provide for proper dust removal, Use dust collection system whenever possible, Exposure to the dust may cause serious and permanent respiratory or other injury, including silicosis (a serious lung disease), cancer, and death, Avoid breathing the dust, and avoid prolonged contact with dust, Allowing dust to get into your mouth or eyes, or lay on your skin may promote absorption of harmful material, Always use properly fitting NIOSH/OBHA approved respiratory protection appropriate for the dust exposure, and wash exposed areas with soap and water, 5, ALWAYS keep the work area clean, well lit, and organized, DO NOT work in an environment with floor surfaces that are slippery from debris, grease, and wax, 6, ALWAYS unplug the tool from the electrical receptacle when making adjustments, changing parts or performing any maintenance, 7, AVOID ACCIDENTAL STARTING, Make sure that the power switch is in the "OFF" position before plugging in the power cord to the electrical receptacle, 8, AVOID A DANGEROUS WORKING ENVIRONMENT. DO NOT Use electrical tools in a damp environment or expose them to rain. 9, CHILDPROOF THE WORKSHOP AREA by removing switch keys, unplugging tools from the electrical receptacles, and using padlocks, 10, DO NOT use electrical tools in the presence of flammable liquids or gasses, 11, DO NOT FORCE THE TOOL to perform an operation for which it was not designed, it wiii do a safer and higher quality job by only performing operations for which the tool was intended, 12, DO NOT stand on a tool, Serious injury could result if the tool tips over or you accidentally contact the tool, 13, DO NOT store anything above or near the tool where anyone might try to stand on the tool to reach it, 14, DO NOT operate tool if under the influence of drugs or alcohol, 15, EACH AND EVERY TIME, CHECK FOR DAMAGED PARTS PRIOR TO USING THE TOOL. Carefully check all guards to see that they operate properly, are not damaged, and perform their intended functions, Check for alignment, binding or breaking of moving parts, A guard or other part that is damaged should be immediately repaired or replaced, 16, GROUND ALL TOOLS, if the tool is supplied with a 3-prong plug, it must be plugged into a 3-contact electrical receptacle, The 3rd prong is used to ground the tool and provide protection against accidental electric shock, DO NOT remove the 3rd prong, See Grounding instructions, 17, KEEP VISITORS AND CHILDREN AWAY from the drill press, DO NOT permit people to be in the immediate work area, especially when the electrical tool is operating, 18, KEEP PROTECTIVE GUARDS IN PLACE AND IN WORKING ORDER, 19, MAINTAIN YOUR BALANCE. DO NOT extend yourself over the tool. Wear oil resistant rubbersoled shoes. Keep floor clear of debris, grease, and wax,