Craftsman 22901 Instruction Manual - Page 7

Goggles are available at Sears Retail Stores. - drill press manual

|

View all Craftsman 22901 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

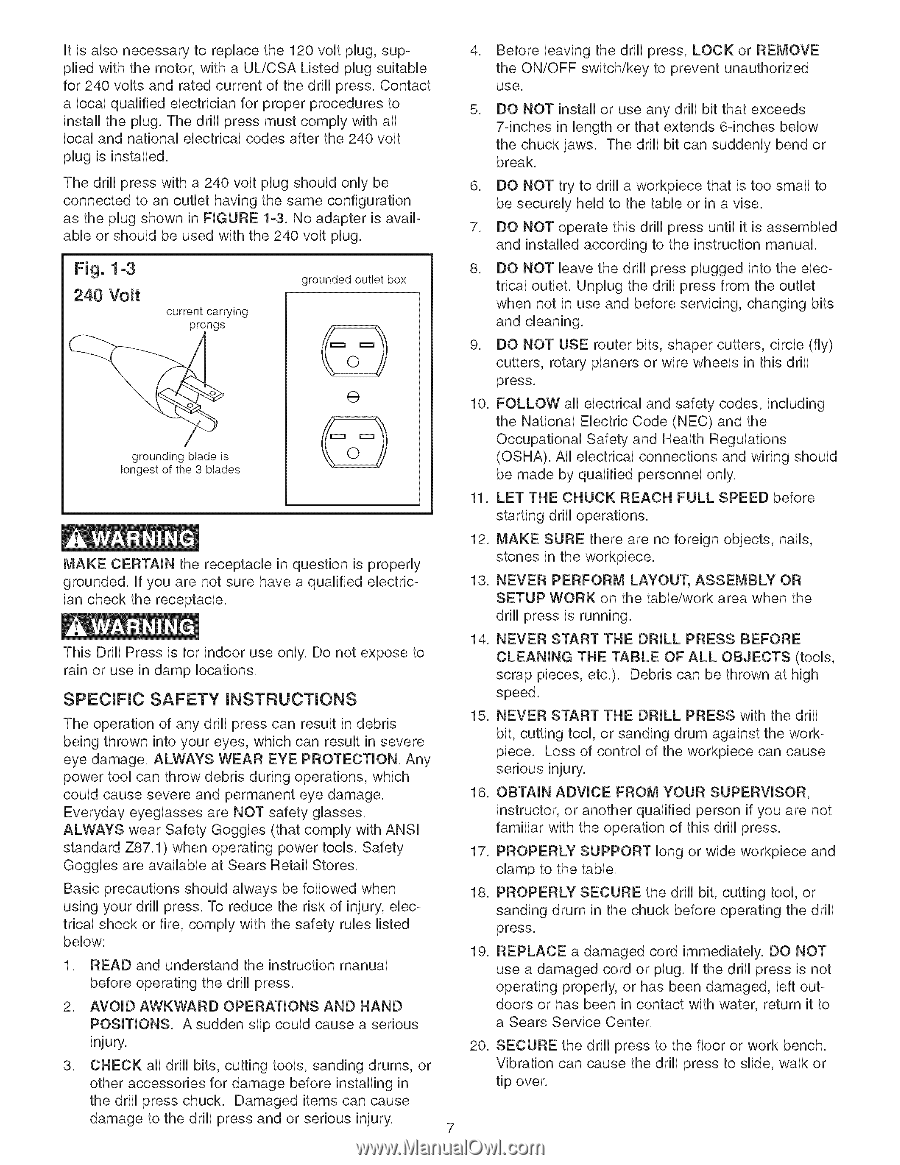

it is aUsonecessary to repUace the 120 voUtpUug,supplied with the motor, with a UL/CSA Listed pUugsuitabb for 240 voUts and rated current of the drHUpress. Contact a bcaU qualified eUectrbian for proper procedures to install the pUug.The drHUpress must compUy with aH bcaU and nationaU eUectrbaUcodes after the 240 voUt pUugis installed. The drHUpress with a 240 voUtpUugshouUd onUybe connected to an outlet having the same configuration as the pUugshown in FIGURE 1-3. No adapter is avaiP able or should be used with the 240 volt plug. Fig. 1-3 240 Volt current carrying prongs grounded outlet box 6) grounding blade is longest of the 3 blades MAKE CERTAIN the receptacle in question is properly grounded. If you are not sure have a qualified ebctrician check the receptacle. This Drill Press is for indoor use only. Do not expose to rain or use in damp locations. SPECIFIC SAFETY INSTRUCTIONS The operation of any drill press can result in debris being thrown into your eyes, which can result in severe eye damage. ALWAYS WEAR EYE PROTECTION. Any power tool can throw debris during operations, which could cause severe and permanent eye damage. Everyday eyeglasses are NOT safety glasses. ALWAYS wear Safety Goggles (that comply with ANSI standard Z87.1) when operating power tools. Safety Goggles are available at Sears Retail Stores. Basic precautions should always be followed when using your drill press. To reduce the risk of injury, ebctrical shock or fire, comply with the safety rules listed below: 1. READ and understand the instruction manual before operating the drill press. 2, AVOID AWKWARD OPERATIONS AND HAND POSITIONS. A sudden slip could cause a serious injury. 3. CHECK all drill bits, cutting tools, sanding drums, or other accessories for damage before installing in the drill press chuck. Damaged items can cause damage to the drill press and or serious injury. 4. Before leaving the drill press, LOCK or REMOVE the ON/OFF switch/key to prevent unauthorized use, 5, DO NOT install or use any drill bit that exceeds 7-inches in length or that extends 6-inches below the chuck jaws. The drill bit can suddenly bend or break. 6. DO NOT try to drill a workpiece that is too small to be securely held to the table or in a vise. 7. DO NOT operate this drill press until it is assembled and installed according to the instruction manual. 8. DO NOT leave the drill press plugged into the ebctrical outlet. Unplug the drill press from the outlet when not in use and before servicing, changing bits and cleaning. 9. DO NOT USE router bits, shaper cutters, circle (fly) cutters, rotary planers or wire wheels in this drill press. 10. FOLLOW all electrical and safety codes, including the National Electric Code (NEC) and the Occupational Safety and Health Regulations (OSHA). All electrical connections and wiring should be made by qualified personnel only. 11, LET THE CHUCK REACH FULL SPEED before starting drill operations, 12, MAKE SURE there are no foreign objects, nails, stones in the workpiece. 13, NEVER PERFORM LAYOUT, ASSEMBLY OR SETUP WORK on the tabb/work area when the drill press is running, 14, NEVER START THE DRILL PRESS BEFORE CLEANING THE TABLE OF ALL OBJECTS (tools, scrap pieces, etc.). Debris can be thrown at high speed. 15. NEVER START THE DRILL PRESS with the drill bit, cutting tool, or sanding drum against the workpiece. Loss of control of the workpiece can cause serious injury, 16, OBTAIN ADVICE FROM YOUR SUPERVISOR, instructor, or another qualified person if you are not familiar with the operation of this drill press, 17, PROPERLY SUPPORT long or wide workpiece and clamp to the table, 18, PROPERLY SECURE the drill bit, cutting tool, or sanding drum in the chuck before operating the drill press, 19, REPLACE a damaged cord immediately, DO NOT use a damaged cord or plug, if the drill press is not operating properly, or has been damaged, left outdoors or has been in contact with water, return it to a Sears Service Center, 20, SECURE the drill press to the floor or work bench, Vibration can cause the drill press to slide, walk or tip over,