Dell Force10 E300 Installing and Maintaining the E300 System - Page 31

Installing RPMs, Line Cards, and SFMs, RPMs, Blank Panels, Unpacking Cards

|

View all Dell Force10 E300 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 31 highlights

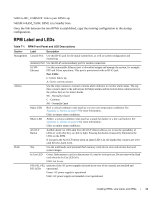

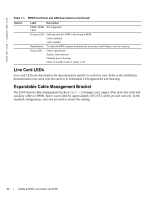

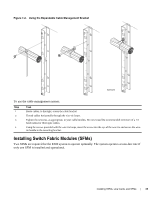

7 Installing RPMs, Line Cards, and SFMs The E300 System accommodates six line cards, two Route Processor Module (RPMs), and two Switch Fabric Modules (SFMs). RPMs The E300 system requires the installation of at least one RPM, although two are recommended for redundancy. RPMs are designed to be installed in either the R0 or R1 slot. Do not force RPMs into line card slots. RPMs are keyed differently than line cards to prevent improper installation. You can hot-insert a second RPM into a running system without performance interruption or software intervention. A second RPM for redundant functionality provides uninterrupted operability if the system transitions from the active RPM to the standby RPM. The standby RPM constantly performs updates and receives the same configuration information received by the active RPM. The standby RPM also performs diagnostics on its subsystems. In the event of a switch over, the standby RPM immediately takes over and resumes the control activities that the active RPM was performing. Installing a Second RPM on page 32 provides more information on the second RPM. You can hot-insert a second RPM into a running system without performance interruption or software intervention. A second RPM for redundant functionality provides uninterrupted operability if the system transitions from the active RPM to the standby RPM. The standby RPM constantly performs updates and receives the same configuration information received by the active RPM. The standby RPM also performs diagnostics on its subsystems. In the event of a switchover, the standby RPM immediately takes over and resumes the control activities that the active RPM was performing. Installing a Second RPM provides more information on the second RPM. The RPM Major and Minor Alarm LEDs are controlled by software that sets the threshold levels for triggering the different alarm stages. Blank Panels CAUTION: To ensure clean air and emission integrity (EMI), install blank panels for RPMs and line cards slots not in use. Always replace cards or blank panel immediately. Blank panels for RPMs and line cards must be installed in empty slots to control airflow. Blank panels are shipped with the system to ensure that all chassis slots are installed with operational modules or blanks. The blank panels do not have board components or connector pins. Align the blank with the guides and gently slide toward the backplane. Unpacking Cards WARNING: Electrostatic discharge (ESD) damage can occur when components are mishandled. Always wear an ESD-preventive wrist or foot-heel ground strap when handling RPMs, SFMs, or line cards. Place RPMs, SFMs, and line cards on an antistatic surface when they are not installed. Installing RPMs, Line Cards, and SFMs | 31