Dewalt DXGNR5700 Instruction Manual - Page 23

Troubleshooting, Know Generator Limits, Know Generator, Limits

|

View all Dewalt DXGNR5700 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 23 highlights

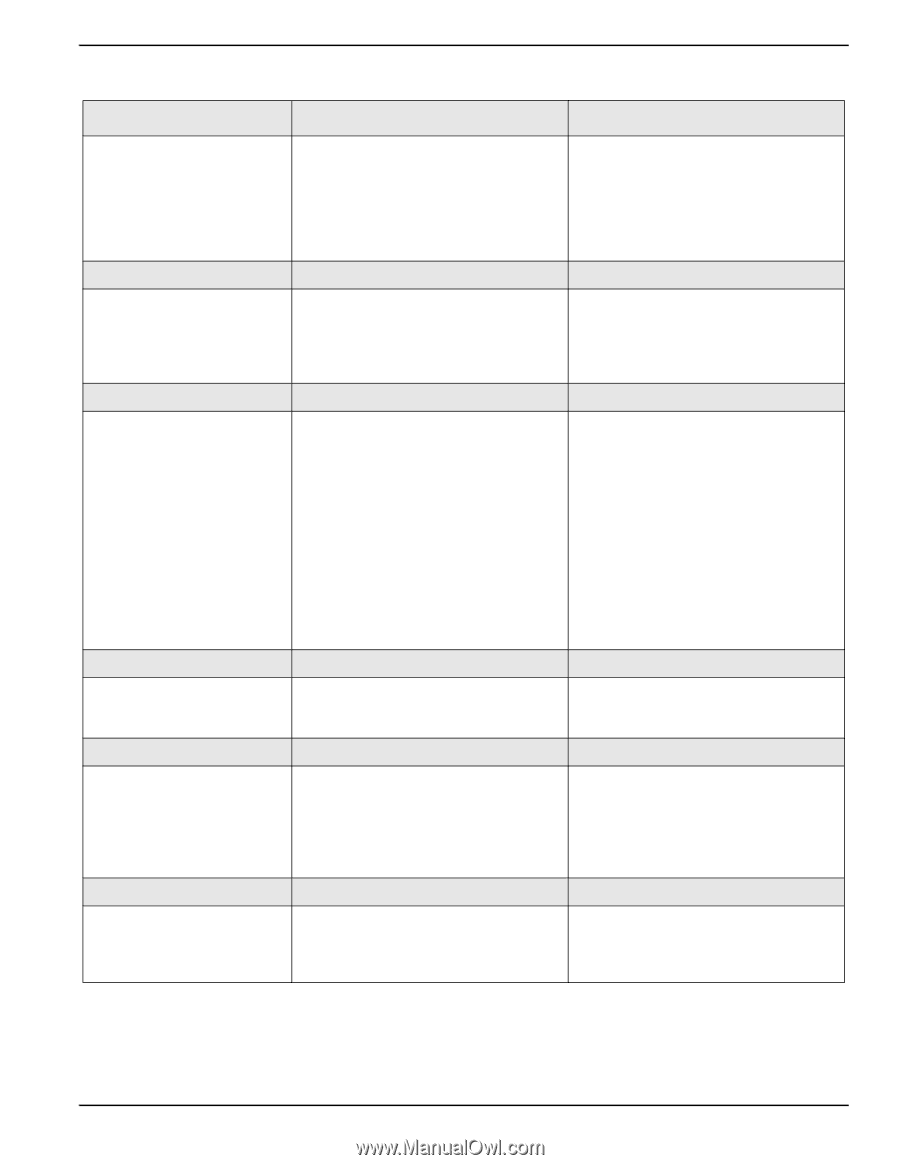

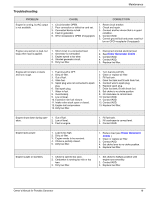

Troubleshooting Maintenance PROBLEM CAUSE CORRECTION Engine is running, but AC output is not available. 1. Circuit breaker OPEN. 2. Poor connection or defective cord set. 3. Connected device is bad. 4. Fault in generator. 5. GFCI receptacle is OPEN (if equipped). 1. Reset circuit breaker. 2. Check and repair. 3. Connect another device that is in good condition. 4. Contact IASD. 5. Correct ground fault and press reset but- ton on GFCI receptacle (if equipped). Engine runs well at no-load, but bogs when load is applied. 1. Short circuit in a connected load. 2. Generator is overloaded. 3. Engine speed is too slow. 4. Shorted generator circuit. 5. Dirty fuel filter. 1. Disconnect shorted electrical load. 2. See Know Generator Limits . 3. Contact IASD. 4. Contact IASD. 5. Replace fuel filter. Engine will not start; or starts and runs rough. 1. Fuel shut-off is OFF. 2. Dirty air filter. 3. Out of fuel. 4. Stale fuel. 5. Spark plug wire not connected to spark plug. 6. Bad spark plug. 7. Water in fuel. 8. Overchoking. 9. Low oil level. 10. Excessive rich fuel mixture. 11. Intake valve stuck open or closed. 12. Engine lost compression. 13. Dirty fuel filter. 1. Turn fuel shut-off ON. 2. Clean or replace air filter. 3. Fill fuel tank. 4. Drain fuel tank and fill with fresh fuel. 5. Connect wire to spark plug. 6. Replace spark plug. 7. Drain fuel tank; fill with fresh fuel. 8. Set choke to no choke position. 9. Fill crankcase to correct level. 10. Contact IASD. 11. Contact IASD. 12. Contact IASD. 13. Replace fuel filter. Engine shuts down during operation. 1. Out of fuel. 2. Low oil level. 3. Fault in engine. 1. Fill fuel tank. 2. Fill crankcase to correct level. 3. Contact IASD. Engine lacks power. 1. Load is too high. 2. Dirty air filter. 3. Engine needs to be serviced. 4. Choke is partially closed. 5. Dirty fuel filter. 1. Reduce load (see Know Generator Limits ). 2. Clean or replace air filter. 3. Contact IASD. 4. Set choke lever to no choke position. 5. Replace fuel filter. Engine surges or stumbles. 1. Choke is opened too soon. 2. Carburetor is running too rich or too lean. 3. Dirty fuel filter. 1. Set choke to halfway position until engine runs smoothly. 2. Contact IASD. 3. Replace fuel filter. Owner's Manual for Portable Generator 19