Epson 2070 Service Manual - Page 64

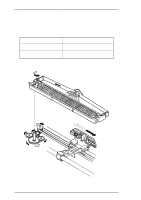

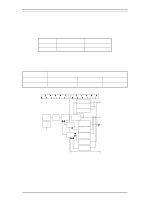

Ribbon Advance Mechanism, Table 2-4. Ribbon Advance Gear Linkage

|

UPC - 010343812277

View all Epson 2070 manuals

Add to My Manuals

Save this manual to your list of manuals |

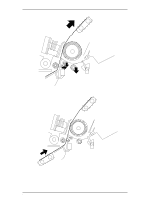

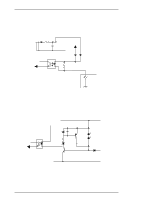

Page 64 highlights

Operation Principles LQ-2070 Servcie Manual 2.1.6 Ribbon Advance Mechanism The ribbon is held between the ribbon advance roller (ribbon driven gear) and the ribbon pressure roller. When the carriage moves from left to right and vice versa on the CR guide shaft, the timing belt turns the belt-driven pulley. Then the torque is transmitted to the ribbon driving gear through the gear trains. The ribbon driving gear rotates counterclockwise, no matter what direction the carriage moves, because a planetary gear is used in the gear linkage. Table 2-4. Ribbon Advance Gear Linkage Direction of Carriage Movement Gear Linkage Left to right (indicated by the black arrow) Belt driven pulley → Gear (1) → Gear (2) → Ribbon driving gear Right to light (indicated by the white arrow) Belt driven pulley → Gear (1) → Gear (3) → Gear (4) → Ribbon driving gear The ribbon brake spring, attached to the exit of the cartridge case, prevents slack in the ribbon and keeps the ribbon tension at an appropriate level. The ribbon mask prevents the ribbon from brushing against the paper. Figure 2-21 Ribbon Advance Mechanism 2-16 Rev.A