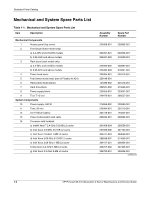

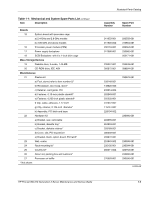

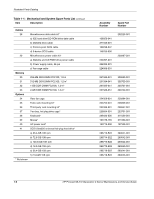

HP ML370 ProLiant ML370 Generation 3 Server Maintenance and Service Guide - Page 16

Removal and Replacement Procedures, Safety Considerations, Electrostatic Discharge

|

UPC - 613326765616

View all HP ML370 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 16 highlights

2 Removal and Replacement Procedures This chapter provides subassembly/module-level removal and replacement procedures for the server. After completing all necessary removal and replacement procedures, run the Diagnostics program to verify that all components operate properly. You may need the following: • Torx T-15 tool (ships standard with the server) • Diagnostics Utility-The Diagnostics utility tests the operation of server hardware and isolates failed parts, whenever possible. Diagnostic error codes are generated when the Diagnostics utility recognizes a problem. These error codes help identify defective components. A Diagnostics diskette can be made by running the Server Diagnostics file available for download from the following website: www.hp.com/servers/manage/ Safety Considerations Before performing service procedures, review the following safety information. Electrostatic Discharge A discharge of static electricity can damage static-sensitive devices or microcircuitry. Proper packaging and grounding techniques are necessary precautions to prevent damage. To prevent electrostatic damage, observe the following precautions: • Transport products in static-safe containers such as conductive tubes, bags, or boxes. • Keep electrostatic-sensitive parts in their containers until they arrive at static-free stations. • Cover workstations with approved static-dissipating material. Use a wrist strap connected to the work surface and properly grounded tools and equipment. • Keep work area free of nonconductive materials such as ordinary plastic assembly aids and foam packing. • Always be properly grounded when touching a static-sensitive component or assembly. • Avoid touching pins, leads, or circuitry. • Always place drives PCB assembly-side down. HP ProLiant ML370 Generation 3 Server Maintenance and Service Guide 2-1