Konica Minolta PKG-675i PKG-675i User Manual - Page 113

Print Quality, PQ Defects, Solution, Cross, Contamination, Vertical Bands of, Incorrect Color

|

View all Konica Minolta PKG-675i manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 113 highlights

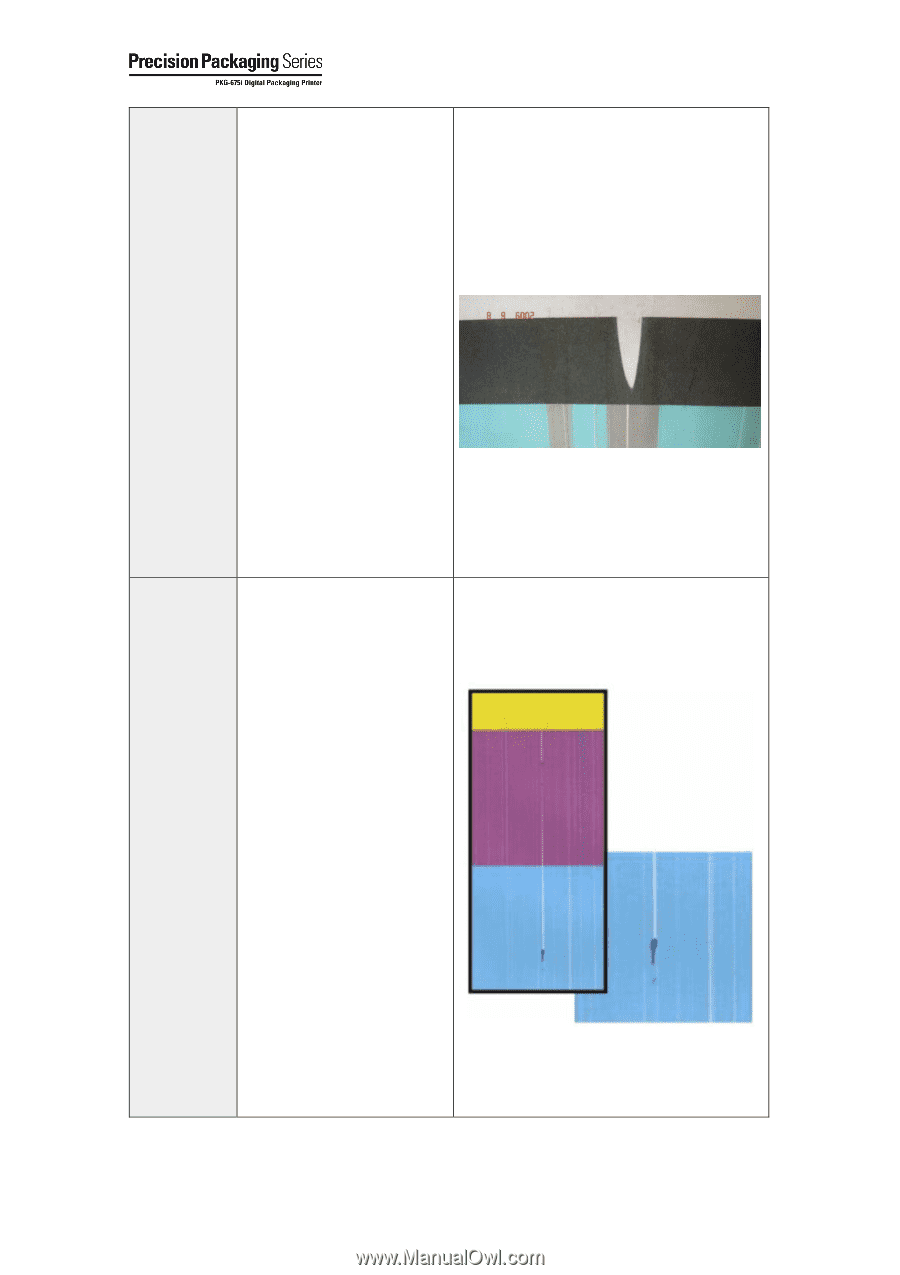

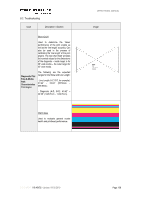

Print Quality (PQ) Defects Nozzle Area Puddle This defect is characterized by a smooth, parabolic area of non-printing (missing jets) followed by a column of printed image exhibiting ink mixing / cross-contamination. This is caused by a small puddle or drop of ink in the nozzle region of the printhead that prevents ejection of drops. The mass of ink eventually absorbs into adjacent nozzles causing color mixing. Solution As can be observed in the accompanying illustration, the missing jets portion of this defect is self-correcting. With regards to its evolution into the defect Cross Contamination - Vertical Bands of Incorrect Color, many times Cross Contamination will be eliminated during the printing of the next plot. Print Quality (PQ) Defects Dripping Ink Missing jets followed by a dark spot. This defect occurs when a droplet of ink has built up on the nozzle area of the Printhead, blocking the ejection of jetted drops. In some cases, ejected drops can be adding to the mass of the offending droplet. After a while, the droplet falls off of the face of the Printhead and lands on the media, creating an abnormally large spot. The build-up of enough ink in the nozzle area of to create this defect can be caused by a number of reasons including inadequate Printhead maintenance by the Service Station, or the presence of paper fibers that block nozzles. Solution The area of a printhead that is exhibiting this behaviour should be adequately cleaned after returning to the "Capped" state. This occurs 20 seconds after the completion of a print job. If the problem is a persistent one, then perform a "level 2 recovery". DOCUMENT I 18.40V02 - Update: 04.09.2019 OPERATIONAL MANUAL Page 113