Pfaff Varimatic 6091 Owner's Manual - Page 60

Faults, remedy, Machine, skips, stitches, Wrong, needle, used., Needle, thread, breaks, uniform - threading

|

View all Pfaff Varimatic 6091 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 60 highlights

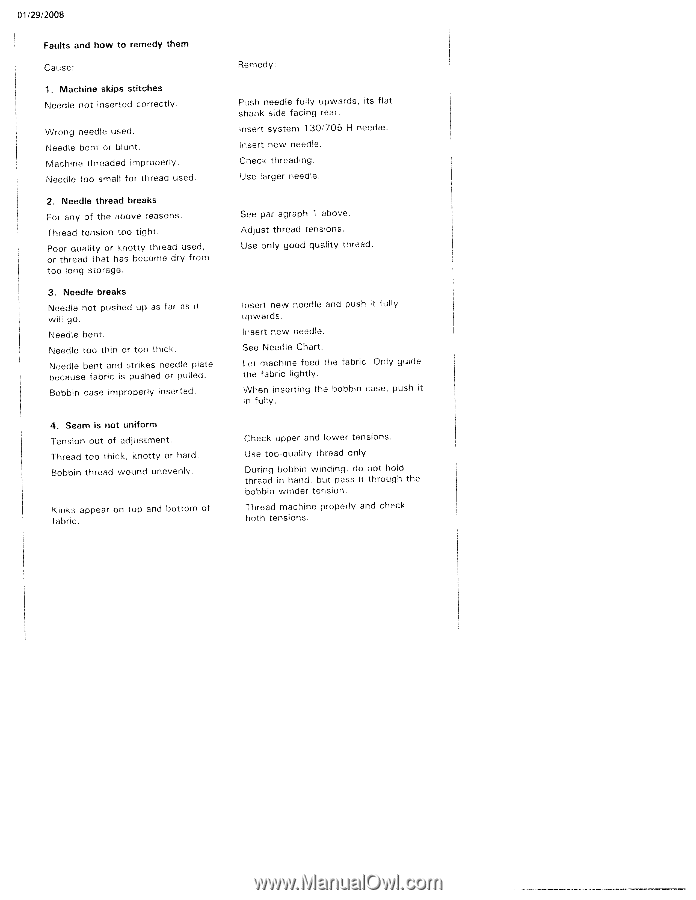

01/29/2008 Faults and how to remedy them Cause: 1. Machine skips stitches Needle not inserted correctly. Wrong needle used. Needle bent or blunt. Machine threaded improperly. Needle too small for thread used. 2. Needle thread breaks For any of the above reasons. Thread tension too tight. Poor quality or knotty thread used. or thread that has become dry from toolong storage, 3. Needle breaks Needle not pushed up as far as it will go. Needle bent. Needle too thin or too thick. Needle bent and strikes needle plate because fabric is pushed or pulled. Bobbin case improperly inserted. 4. Seam is not uniform Tension out of adjustment. Thread too thick, knotty or hard. Bobbin thread wound unevenly Kinks appear on top and bottom of fabric. Remedy Push needle fully upwards, its flat shank side facing rear. Insert system 130, 705 H needle. Insert new needle. Check threading. Use larger needle. See par agraph 1 above. Adjust thread tensions. Use only good quality thread. Insert new needle and push it fully upwards. Insert new needle. See Needle Chart. Let machine feed the fabric. Only guide the fabric lightly. When inserting the bobbin case, push it in fully. Check upper and lower tensions. Use topquality thread only, During bobbin winding, do not hold thread in hand, but pass it through the bobbin winder tension. Thread machine properly and check both tensions.