Ridgid R4512 Owners Manual - Page 30

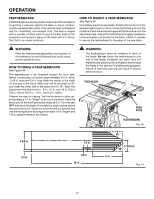

How To Make A Jig For Rip Cutting

|

View all Ridgid R4512 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 30 highlights

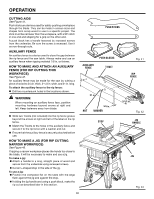

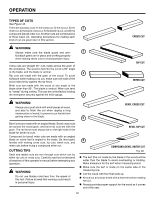

OPERATION cutting aids See Figure 41. Push sticks are devices used for safely pushing a workpiece through the blade. They can be made in various sizes and shapes from scrap wood to use in a specific project. The stick must be narrower than the workpiece, with a 90˚ notch in one end and shaping for a grip on the other end. A push block has a handle fastened by recessed screws from the underside. Be sure the screw is recessed. Use it on non-through cuts. AUXILIARY FENCE An auxiliary fence is a device used to close the gap between the rip fence and the saw table. Always make and use an auxiliary fence when ripping material 1/8 in. or thinner. How to Make and ATTACH an auxiliary fence (for rip cutting thin workpiece) See Figure 42. An auxiliary fence may be made for the saw by cutting a piece of wood to 3/4 in. thick, 3-1/2 in. wide, and 31 in. long. To attach the auxiliary fence to the rip fence: Drill two countersunk holes in the locations shown. WARNING: When mounting an auxiliary fence face, position mounting hardware beyond arrows at right and left. Keep fasteners away from blade. Slide two T-bolts (not included) into the rip fence groove beyond the arrows at right and left of the label on the rip fence. Match the T-bolts to the holes in the auxiliary fence and secure it to the rip fence with a washer and nut. Ensure that the auxiliary fence is securely attached before use. How to Make a jig (for rip cutting narrow workpiece) See Figure 43. If ripping a narrow workpiece places the hands too close to the blade, it will be necessary to make and use a jig. To make a jig: Attach a handle to a long, straight piece of wood and secure from the underside using recessed screws. Cut an L-shaped stop in the side of the jig. To use a jig: Position the workpiece flat on the table with the edge flush against the jig and against the stop. Holding the jig handle and using a push block, make the rip cut as described later in this section. PUSH STICKS PUSH BLOCKS AUXILIARY FENCE T-bolt Fig. 41 rip fence 31 in. 3/4 in. nut washer STOP 3-1/2 in. Fig. 42 jig handle jig Fig. 43 30