Ridgid R4512 Owners Manual - Page 49

Maintenance - replacement fence

|

View all Ridgid R4512 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 49 highlights

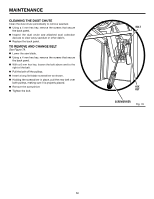

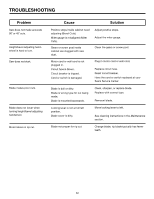

MAINTENANCE warning: When servicing, use only identical RIDGID replacement parts. Use of any other parts may create a hazard or cause product damage. WARNING: Always wear safety goggles or safety glasses with side shields during power tool operation or when blowing dust. If operation is dusty, also wear a dust mask. WARNING: Before performing any maintenance, make sure the tool is unplugged from the power supply and the switch is in the OFF ( O ) position. Failure to heed this warning could result in serious personal injury. GENERAL MAINTENANCE Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of commercial solvents and may be damaged by their use. Use clean cloths to remove dirt, dust, oil, grease, etc. WARNING: Do not at any time let brake fluids, gasoline, petroleum-based products, penetrating oils, etc., come in contact with plastic parts. Chemicals can damage, weaken or destroy plastic which may result in serious personal injury. Periodically check all clamps, nuts, bolts, screws, and belts for tightness and condition. Make sure the throat plate is in good condition and in position. Check the blade guard assembly. To maintain the table surfaces, fence, and rails, periodically apply paste wax to them and buff to provide smooth functioning. To prevent work from slipping during cutting operation, Do not wax the working face of the miter gauge. Protect the blade by cleaning out saw dust from underneath the table and in the blade teeth. Use a resin solvent on the blade teeth. Clean plastic parts only with a soft damp cloth. Do not use any aerosol or petroleum solvents. LUBRICATION This saw's motor bearings have been packed at the factory with proper lubrication. Clean screw threads and nuts with a solvent recommended for gum and pitch removal. Lubricate screw threads, nuts, and bearing points (including those on the blade guard assembly and miter gauge). 49