Craftsman 21829 Operation Manual - Page 42

TO SET THE B_VEL - extension

|

View all Craftsman 21829 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 42 highlights

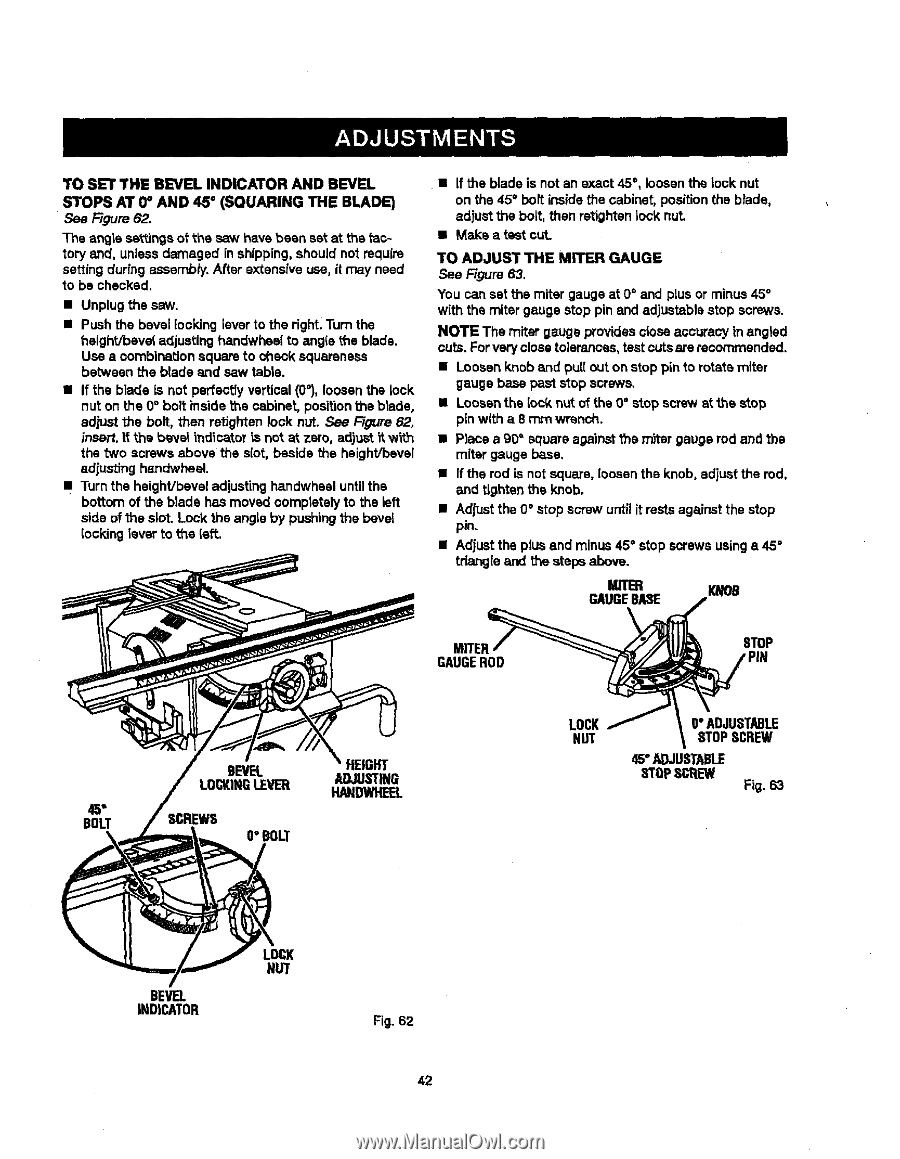

TO SET THE B_VEL INDICATOR AND BEVEL STOPS AT 0_ AND 45 ° (SQUARING THE BLADE) Figure 62. The angle sa_mgs oFthe saw have been set at the _actory and, unlessdamaged in shipping, should not require setting during assembly. After extensive use, it may need to be checked. • Unplug the saw. • Push the bevel looking lever to the right.Turn the t_eight/beve{ adjusting handwhsel to angle L'heblade. Use • combinationsquare to check squareness between the blade and saw table. • If the blade is not perfectly vertical (0_),loosen the lock nut on the 0° bolt _nside the cabinet, positionthe blade, adjust the bolt, then retighten lock nut. See Figure 62, insall, if the banal indicator is not at zero, adjust_tw_.h the "twoscrews above the slot, beside the heighVbevel adjusting handwheel. • Turn the heighVbevel adjusting ha.ndwhesluntilthe bottom of the blade has moved completelyto the left side of the slot. Lock the angle by pushing the bevel _ocking lever to the left. • If the blade is not an exact 45 °, loosenthe lock nut on the 45° bolt inside the cabinet, positionthe blade, adjust the bolt, then retighten lock nut. • Make a test cut. TO ADJUST THE MITER GAUGE See Figure 63. You can set the miter gauge at O° and plus or minus 45° with the miter gauge stop pin and adjustablestop screws. NOTE The miter gauge providesclose accuracy in angled cuts. Forvery close tolerances,test cutsare recommended. • Loosen knob and pull out on stop pin to rotate miter gauge base paststop screws. • Loosenthe lock n_t of the 0 ° stop screw st the stop pinwith a 8 rnm wrench. • Place a 90" squareagainstthe m_ar gauge rod and the miter gauge base. • If the rod is not square, loosenthe knob, adjust the rod, and tighten the knob. • Adjust the 0 ° atop screw until it restsagainst the stop pin. • Adjust the plus end minus 45° stop screws usinga 45 ° triangle and the stepsabove. MITER GAUGEBASE m MITER_ BOLT GAUGEROD BEVEL LOCKINGLEVEE[ ADHJEUIGSHTITNG HANDWHEEL O"BOLT LOCK/ NUT O"ADJUSTABLE STOPSCREW 45"ADJUSTABLE STOPSCREW Fig. 63 BEVEL INDICATOR LOCK NUT Fig. 62 42