Craftsman 21829 Operation Manual - Page 45

Recommended Lubricants:Dry Siliconeor Tenon

|

View all Craftsman 21829 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 45 highlights

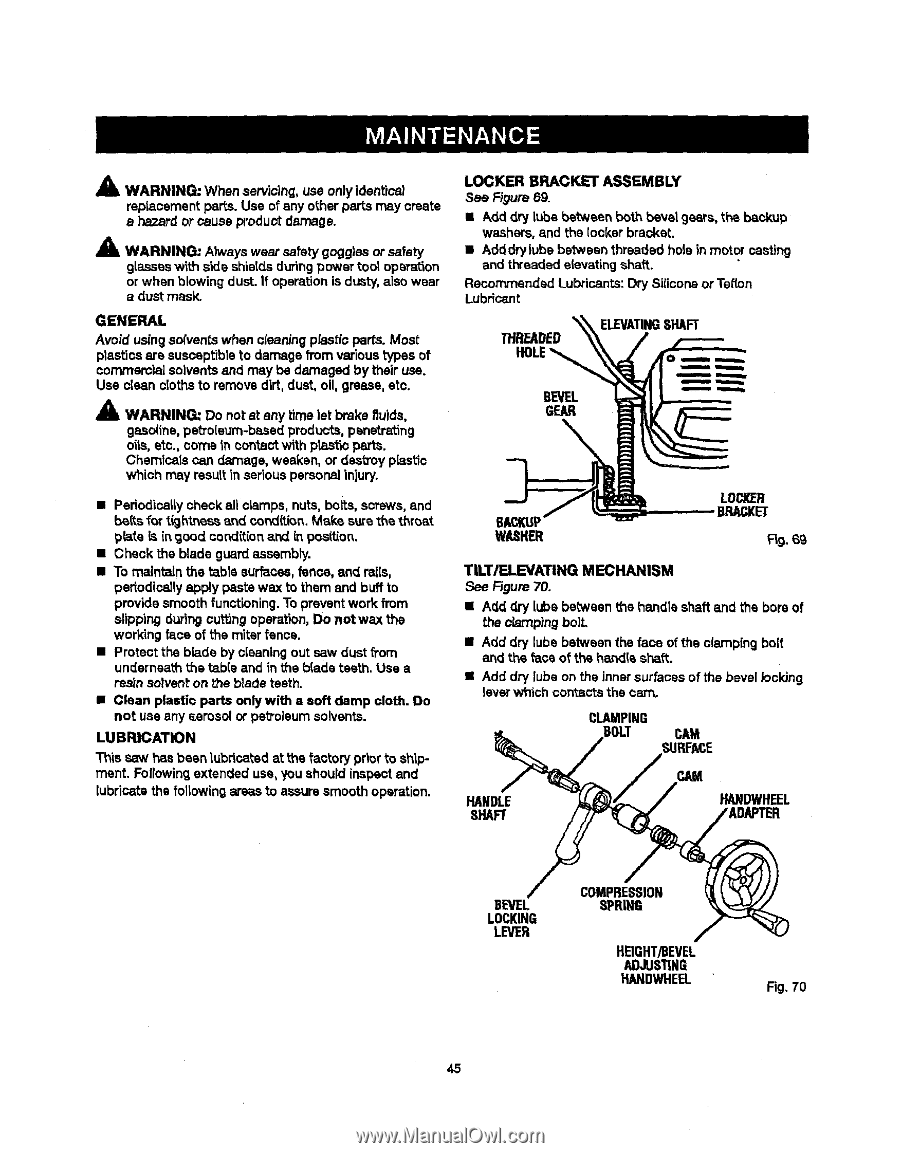

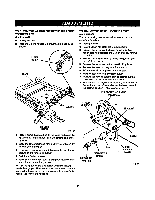

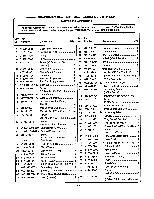

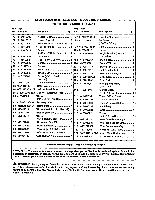

A Am, WARNING: When servicing, use only identice_ repianementpaps. Use of any other parts m_y create a hazardorcause product damage. A Am. WARNING: A_vays wear safety goggles or safety glasses with side shietdsduringpower too_opera,on or when blowing dust. If operation is dusty,also wear a dust mask. GENERAL Avoid using so(ventswhen cteaning p_,stioparts. Most plasticsare suscsptibteto damage from various types of commercial solventsend may be damaged by their use. Use clean clothsto remove dirt, dust, o11g, rease, etc. _1_ WARNING: Do not at any Limelet brake fluids, gaso(ine,petro(eum-basedproducts, penetrating oils, etc., come In ¢on_actwith pta_'=oparts. Chemicatscan damage, weaken, or destroyp_stic which may resuttIn serious personalinjury. • Periodicallycheck all clamps, nuts, boits, screws, and _{ts _ar t_hl.r_ss and cond_,_n, Make sure the t_roat p_te is (ngood cond(t(on a.nd_. position. • Check the blade guard assembty. • To maintain the t_bte sur_css, fence, and raits, pedodice]Iyapply paste wax to them and buff to providesmooth functioning. To preventwork from slipping duringcutting operation,Do not wax the working face of the miter fence. • Protect the bb.de by cleaningout saw dust from underneath the _b(e and in the b{ade teeth. Use a reamsolvent on _heb_ade teeth. • Clean plastio parts only with a soft damp cloth. Do not use any aerosol or petroleumsolvents. LUBRICATION This saw has been lubricated at the factory priorto shipment. Foflowingextended use, you should inspectand lubricate the following areasto assure smooth operation. LOCKER BRACKET ASSEMBLY See Figure69. • Add dry lube between both bevel gears, theb_ckup washers,and the locker braoket.. • Adddrylubs be_:weenthreaded hole in motor casting and threaded elevatingshaft. Recommended Lubricants:Dry Siliconeor Tenon Lubricant THREADED ELEVATINGSHAFT HOLE BEVEL GEAR TILT/ELEVATING MECHANISM See _gure 70. • Add dry [ube between me handle shaft and the boreof the P.,bmpingboil • Add dry lube between the face of the clampingbolt and theface of the handle sh_ft. • Add dry lube on the inner surfaces of the bevel Ioclong lever which corr_sctsthe cam. CLAMPING BOLT CAM SURFACE HANDLE SHAFT CAM HANDWHEEL BEVEL LOCKING LEVER COMPRESSION SPRING HEIGHT/BEVEL ADJUSTING HANDWHEEL Fig. 70 45