Haier 3U19FS1ERA Service Manual - Page 45

ÂûµÄÅ

|

View all Haier 3U19FS1ERA manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 45 highlights

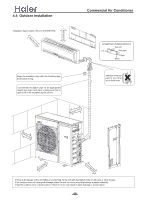

>_]]VbTZR\ _^UZdZ_^Vb 5. Refilling the refrigerant Check the type of refrigerant to be used on the machine namiplate. Precautions when adding R410A Fill from the liquid pipe in liquid form. It is a mixed refrigerant, so adding it in gas form may cause the refrigerant composition to change, preventing normal operation. 1) Before filling, check whether the cylinder has a siphon attached or not.(It should have something like "liquid filling siphon attached" displayed on it.) Filling a cylinder with an attached siphon Filling other cylinders Stand the cylinder upright when filling. There is a siphon pipe inside, so the cylinder need not be upside-down to fill with liquid. Turn the cylinder upside-down when filing. 2) Be sure to use the R410A tools to ensure pressure and to prevent foreign objects entering. 6. Charging with refrigerant 1) This system must use refrigersant R410A. 2) Add refrigerant 20g per meter when the total piping length exceeds the standard value, but make sure that the total liquid piping length should be less than the max. value. Notes: 1) When using this product, you need not to set the address. But the L/N wires between indoor & outdoor units must be corresponded, or there will be communication failure. 2) Quiet Operation Setting. Set the DIP "8" to ON position of SW5, the system will run with lower noise, but the max. capacity will also reduce slightly. 3) Do not change the settings of other switchs, wrong settings can make the system damage or other malfunctions. 7.Precautions for Laying Refrigerant Piping Cautions on pipe handling 1) Protect the open end of the pipe against dust and moisture. 2) All pipe bends should be as gentle as possible. Use a pipe bender for bending.(Bending radius should be 30 to 40mm or larger.) Selection of copper and heat insulation materials When using commercial copper pipes and fittings, observe the following : 1) Insulation material: Polyethylene foam Heat transfer rate: 0.041 to 0.052W/mK(0.035to 0.045kcal/mhoC) Refrigerant gas pipe's surface temperature reaches 110oC max. Choose heat insulation materials that will withstand this temperature. 2) Be sure to insulate both the gas and liquid piping and to provide insulation dimensions as below. Gas pipe O.D.:9.52mm,12.7mm Thickness:0.8mm Liquid pipe O.D.:6.35mm Thickness:0.8mm Gas pipe insulation I.D.:12-15mm,12.7mm Thickness:13mm min. Liquid pipe insulation I.D.:18-10mm Thickness:10mm min. -44-