Brother International NX-450Q Users Manual - English - Page 27

Installing the bobbin

|

View all Brother International NX-450Q manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 27 highlights

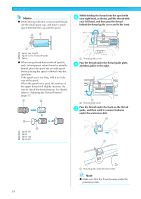

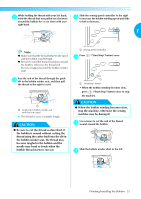

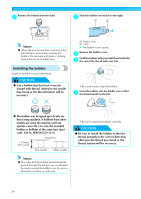

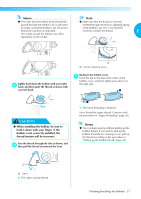

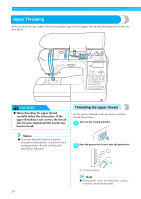

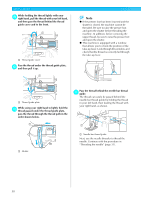

GETTING READY Remove the bobbin from the shaft. q Slide the bobbin cover latch to the right. a 1 2 Memo z When the sewing machine is started or the handwheel is turned after winding the bobbin, the machine will make a clicking sound; this is not a malfunction. Installing the bobbin Install the bobbin wound with thread. CAUTION ● Use a bobbin that has been correctly wound with thread, otherwise the needle may break or the thread tension will be incorrect. a Bobbin cover b Latch X The bobbin cover opens. Remove the bobbin cover. b Hold the bobbin with your right hand and hold c the end of the thread with your left. • Be careful not to drop the bobbin. Insert the bobbin into the bobbin case so that d the thread unrolls to the left. ● The bobbin was designed specifically for this sewing machine. If bobbins from other models are used, the machine will not operate correctly. Use only the included bobbin or bobbins of the same type (part code: SA156, SFB(XA5539-151)). Actual size 11.5 mm (7/16 inch) This model Other model Memo z The order that the bobbin thread should be passed through the bobbin case is indicated by marks around the bobbin case. Be sure to thread the machine as indicated. • Be sure to insert the bobbin correctly. CAUTION ● Be sure to install the bobbin so that the thread unwinds in the correct direction, otherwise the thread may break or the thread tension will be incorrect. 26