Cub Cadet ZT1 42 FAB Operation Manual - Page 24

Storing the Tractor, Maintenance

|

View all Cub Cadet ZT1 42 FAB manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 24 highlights

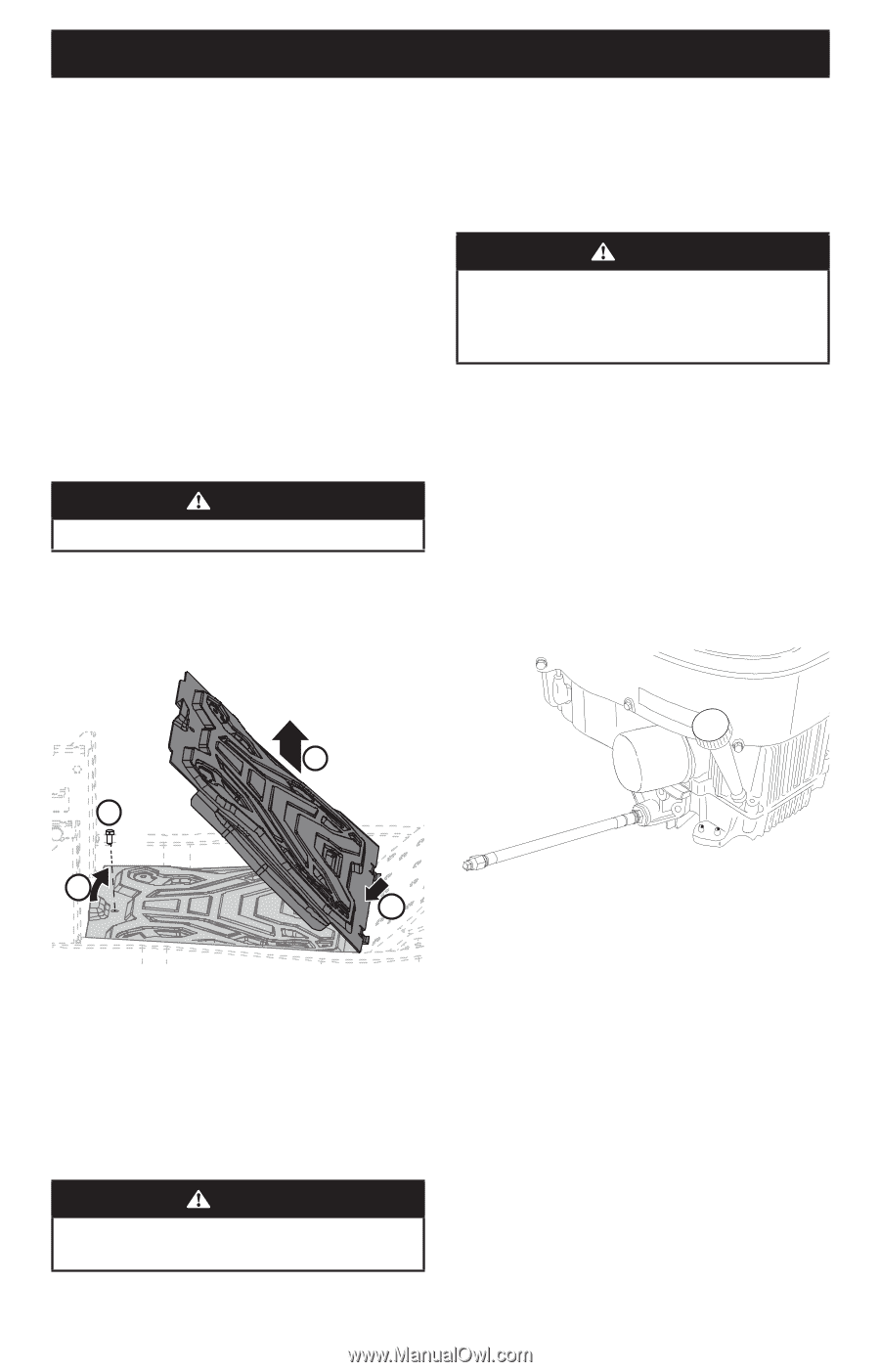

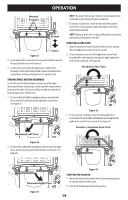

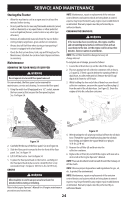

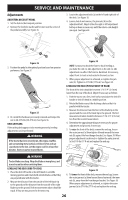

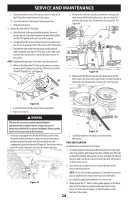

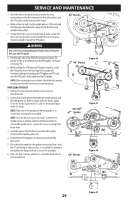

SERVICE AND MAINTENANCE Storing the Tractor • Allow the machine to cool in an open area for at least five minutes before storing. • Do not park the tractor near any flammable materials (wood, cloth or chemicals) or any open flames or other potential source of ignition (furnace, water heater or any other type of heater). • Remove all combustible materials from the tractor before storing. Empty cargo boxes, grass catchers or containers. • Always shut off fuel flow when storing or transporting if tractor is equipped with a fuel shutoff. • Check the fuel system (lines, tank, cap and fittings) per the Maintenance Schedule for cracks or leaks. Repair and clean as necessary. Maintenance REMOVING THE FLOOR PANEL (IF EQUIPPED) WARNING Do not operate tractor with floor panel removed. On some models, the floor panel can be removed for maintenance, service and cleaning. To remove the floor panel: 1. Using the multi-tool (if equipped) or a 1/2" socket, remove the hex screw (a) that secures the floor panel in place. See 1 in Figure 34. NOTE: Maintenance, repair or replacement of the emission control devices and systems which are being done at owner's expense may be performed by any engine repair establishment or individual. Warranty repairs must be performed by an authorized dealer. CHANGING THE ENGINE OIL WARNING If the tractor has been recently run, the engine, muffler, and surrounding metal surfaces will be very hot and can cause burns to the skin. Let the engine cool for at least five minutes. Exercise caution to avoid burns. NOTE: The oil filter should be changed at every oil change interval. To complete an oil change, proceed as follows: 1. Locate the oil drain hose (a) on the side of the engine. 2. Place an appropriate oil collection container with at least a 2.5 quart (2.37 liter) capacity below the opening of the oil drain hose, to collect the used oil. Remove the oil fill cap/ dipstick (b) from the oil fill tube. 3. While holding the free end of the oil drain hose over the oil collection container, unscrew the square head hose plug (c) from the end of the oil drain hose. See Figure 35. Drain the engine oil into the collection container. (b) 4 (d) 1 (a) (a) (c) 2 3 Figure 34 2. Carefully lift the rear of the floor panel. See 2 in Figure 34. 3. Slide the floor panel rearward to free the front of the floor panel. See 3 in Figure 34. 4. Lift it off the tractor. See 4 in Figure 34. 5. To place the floor panel back on the tractor, carefully put the floor panel back in place and re-install the hex screw removed in Step 1. Torque to 108-132 in-lbs (12-15 N-m). ENGINE WARNING Allow machine to cool in an open area for at least five minutes before storing or refueling. Refer to the Engine Operator's Manual for all engine maintenance procedures and instructions. Figure 35 4. After draining the oil, wipe any residual oil from the oil drain hose. Thread the square head hose plug into the oil drain hose fitting and tighten the square head hose plug to 16 ft-lbs (22 N-m). 5. Remove the oil filter (d) and drain into the collection container. 6. Replace the oil filter (d) and refill the engine with new oil as instructed in the Engine Operator's Manual. NOTE: Place an absorbent towel beneath the oil filter to keep oil off the clutch. NOTE: Observe proper disposal laws and regulations for gas, oil, etc. to protect the environment. NOTE: Maintenance, repair or replacement of the emission control devices and systems which are being done at owner's expense may be performed by any engine repair establishment or individual. Warranty repairs must be performed by an authorized dealer. 24