HP Scitex FB500 HP Scitex FB500 and FB700 Printer Series - User Guide - Page 55

Printhead X Calibration, Proceed., Move Belt Forward, Calibrate, Manual Calibrations

|

View all HP Scitex FB500 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 55 highlights

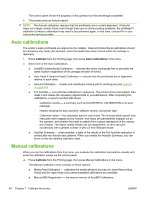

overprinting previous patterns. For best quality when printing on rigid sheet-fed media, position the pattern approximately 20 cm (8 in) from the edge. 4. Use the control panel controls to position the pattern, then press Proceed. The printer prints the registration pattern, then prompts you to advance the media so you can inspect it. 5. Advance the media by pressing Move Belt Forward, then press Proceed. The control panel displays this prompt: Bidi registration Head 1: 0 6. Examine the BiDi Registration pattern for the current head, and determine which pattern is the closest to perfectly aligned. Use a printer's loupe (10X magnification or higher) to select the pattern, since the lines in the patterns may be difficult to see. 7. Press the ▲ or ▼ control panel keys repeatedly until the number next to the pattern that is closest to aligned perfectly is displayed. For example, if pattern +2.0 is the closest aligned, press Proceed to change the display to: Bidi registration Head 1: +2 If a printhead is extremely out of alignment, there may be no pattern in alignment. Since the vertical bars are nominally five pixels apart, you can add +10 or -10 to a pattern number to shift the colored bars right or left by one black bar. Alternatively, you can perform the BiDi Registration repeatedly, which will move the head in smaller increments, until the head is aligned. 8. Press the ▲ button. The control panel message increments the head number by one. 9. Repeat steps 4 through 6 for each of the heads. When you have entered registration values for all heads, the control panel displays this message: Registration Successful Printhead X Calibration Precise positioning of each drop of ink is essential for optimal print quality. This is possible only if you register all printheads in the printhead assembly to each other in the X (along the length of the platen) direction. This is a two-part process: ● Print a registration pattern. ● Enter the X registration data for each head. NOTE: This is the manual version of AutoH2H Calibration (see Auto calibrations on page 46). 1. Press Calibrate from the Printing page, then press Manual Calibrations in the menu. 2. Press Printhead X Calibration in the menu. ENWW Manual calibrations 49